Why use rigid-flex PCB than flexible PCB in electronic project?

When it comes to PCB (printed circuit board), a lot of people think of rigid PCB, and rigid PCB is the most common form of printed circuit fabrication. However, with the increasing demand of smaller devices, PCB manufacturers and engineers are confronted with the challenge of achieving higher performance in smaller and smaller form factors so that meet the demands of customers. So there are two major types of boards widely used in PCB fabrication and assembly with small, faster, flexibility, such as flexible PCB and rigid-flex PCB.

Needless to say, unlike traditional rigid PCB, flexible circuit boards are rolled with copper and similar materials, and the main goal is to provide sufficient flexibility and bending resistance. But flex-rigid PCBs, which are made up of flexible PCB and rigid PCB, as well as have multiple layers of both flexible and rigid technologies so that it could be able to do better at an optimum level without the risk of breaking.

What is flexible PCB?

Flexible PCB, also called flex PCBs, which is a patterned arrangement of printed circuit and components that make use of flexible based material with or without flexible cover layer. The flexible electronic assemblies can fabricate with the component the same as rigid printed circuit boards, however, allowing the board to meet the demands of a necessary shape during its application.

The benefits of flexible PCB

Reduce space and weight: flexible PCB can lead to a space reduction of over 50 percent and a weight reduction of 95 percent, at the same time, keeping the function and reliability of the board.

Minimized errors: flexible PCB reduces the wiring errors because of the elimination of mechanical connectors and reduced variations in assembly methods.

Durability: they can deal with the changing external forces and improve the resistance to shock and vibration, such as flexibility, reduced weight and number of interconnects in PCBs.

Signal integrity: flexible PCB can work well in a wide range of environments, so the signal can perform well no matter what exterior conditions, which improve the signal reliability of PCB.

Heat dissipation: the thinner material of flexible PCB has a greater surface-area-to-volume ratio so that improve heat dissipation.

Low cost: flexible PCB is cost-effective due to the fewer assembly steps involved in the creation of flexible PCB.

High density: the thin layers and smaller parts mean that flexible PCB can allow higher circuit densities.

Flexible PCB fabrications

Flexible PCB is a great choice for medical devices, sensors, implants, and mobile consumer electronics as it fits where space and weight is limited. There are some products that it’s better to use flexible PCB:

Three-dimensional packaging geometry

Shock and vibration resistance

Thin, lightweight products that are durable

Wiring solutions that fit where rigid PCB cannot

Miniaturized versions of existing technologies

Flexible PCB can reduce the size and weight of an application, as well as an ideal for high temperature and high-density applications.

What is rigid-flex PCB?

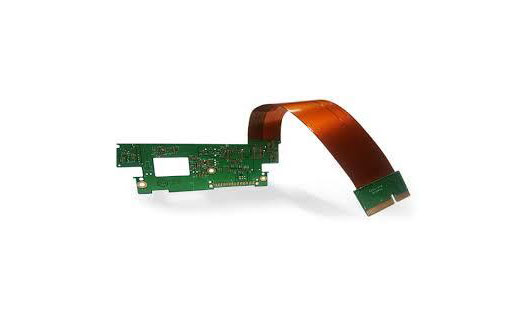

A rigid-flex PCB is a board that is made up of flexible PCB and rigid PCB, and rigid-flex PCB has multiple layers of both flexible and rigid technologies so that it could be able to do better at an optimum level without the risk of breaking. A rigid-flex PCB can be completely custom to meet the demands of application for a variety of vias that are used, materials and track widths.

As you know, the rigid-flex PCB does not be in a fragile state, on the contrary, rigid-flex PCB is in a steady state of a curve. The shape of rigid-flex PCB takes as a spring, which it will go back to its original state if you stretch or compress.

Benefits of Rigid-Flex PCB

An reliable interconnection;

Reduce the costs of logistical and assembly;

A rigid part for mounting the components, a flexible part for the movement;

It’s very reliable and space-saving because of Connections without connectors;

Make it easy to do assembly because of flexibility and lack of connectors connections;

There will not any incorrect assembly owing to the integrated interconnection, which can prevent incorrect assembly during maintenance work;

There will have many options for impedance controlled tracks; it can realize impedance control in both the rigid and the flex parts.

Rigid-flex PCB applications

The rigid-flex PCB has a variety of applications in different kinds of accessories and equipment that are used on a daily basis. One of the most obvious uses is the application of smartphone. In the present, it needs to be incredibly thin but highly functional for the smartphones, and only the rigid-flex technology can it achieve.

Another famous application of rigid-flex PCB is various computer electronics equipment. The hard drive, one of the many components with rigid-flex technology. It can catch up with the ever-increasing write speeds of today’s computer. It’s great for a hard drive to use a rigid-flex PCB, because it can make the hard drive cool down.

In consumer products, rigid-flex PCB doesn't just maximize space and weight but greatly improves reliability, eliminating many needs for solder joints and delicate, fragile wiring that are prone to connection issues. However, rigid-flex PCB can nearly be used to benefit all advanced electrical applications including testing equipment, tools and automobiles.

Why rigid-flex PCB?

Rigid-flex PCBs are a way to remove the electronic design, connectors, flexible cables as well as discrete wiring. Comparing to other boards, it has great electrical performance as the circuits are integral to the overall construction. All of the electrical and mechanical connections are internally contained within the rigid-flex PCB so that it can provide much improved service reliability and electrical performance for electronics designer.

The reasons why rigid-flex PCB is better than rigid PCB and flexible PCB is that it has the advantage of the reliability, weight reduction, strength and space-saving, while rigid-flex PCB gets to a higher cost. What’s more, rigid-flex PCBs provide the best advantages of rigid and flex PCBs in one solution. There is the applications of rigid flex PCB as allows:

High-density applications. Sometimes it’s hard to accept all of the cables and connectors that an electronic PCB design would be necessary within a small enclosure. Needless to say, rigid-flex PCB can fold into the tiny profiles, so it can save more spaces in these cases.

High-reliability applications. It’s possible for the connectors with flexible cables to fail if an assembly will be exposed to excessive or repeated shock, or high vibration environments. Rigid-flex PCB has a great reliability even when subjected to shock applications and extreme vibration.

Five or more rigid PCBs. An integrated rigid flex solution is often the optimal and most cost-effective choice if your application will ultimately involve five or more rigid boards connected to one another with flex cables.