What is the surface finish?

Surface finish is one of the PCB fabrication processes. It is also called surface treatment or surface coating. PCB surface finish acts like a cloth, and it helps to prevent the board from external environmental damage. The PCB may be oxidized or contaminated without this protection. PCB surface finish is a very important process that affects the reliability of PCB assembly and PCBs by protecting copper trace and reinforcing welded connections.

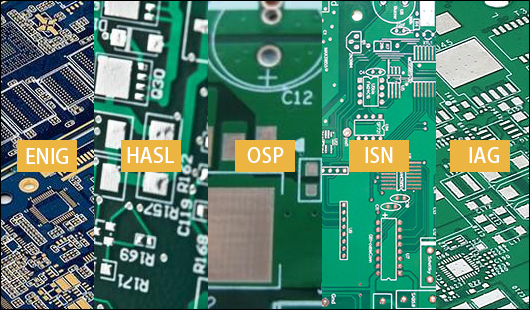

Five types of PCB surface finish

There are several common types of PCB surface finish, and each type has its characteristics, costs, and effects. Then the question is how to choose a suitable surface finish type when are we manufacturing PCBs? We should first know about the different PCB surface finishes and find the one that suits you best.

____________________________________________________________________________________________________________________________

| Hot air solder level (HASL)

There are two kinds of HASL: lead and lead-free. HASL is preferred for manual soldering because it is cheapest and easy to form joints.

Pros:

1. Low cost

2. Robust structure and excellent solderability

3. Long shelf-life

4. Re-workable

Cons:

1. Uneven surface

2. Solder bridging is easy to occur

3. Easy cause PTH plug

4. Not suitable for HDI PCBs

.........................................................................................................................................................................................................................................................

| Organic solderability preservative (OSP)

OSP is an organic finish that is used in copper pads. OSP surface finish is nor conductive. It is RoHS compliant with excellent solderability.

Pros:

1. Low cost

2. Simple manufacturing process

3. Flat surface

4. Suitable for SMT assembly

Cons:

1. Highly sensitive

2. Not suitable for PTH

3. Hard to measure the thickness

4. Limited shelf-life

5. Not conductive

.........................................................................................................................................................................................................................................................

| Electroless nickel immersion gold (ENIG)

ENIG surface finish is a double-layer metal coating with nickel, which can be used as a protective barrier to copper circuits and as a surface for soldered components. ENIG is very suitable for fine-pitch technology, lead-free soldering, SMT, BGA, and aluminum wire bonding.

Pros:

1. Hard and durable, with excellent solderability and long shelf-life

2. Lead-free and RoHS compliant

3. Flat surface

4. Excellent corrosion resistance and high-temperature resistance

5. Simple process mechanism

Cons:

1. Expensive

2. Prone to surface cracks and connection errors

3. Not easy to rework

.........................................................................................................................................................................................................................................................

| Immersion Tin (ISn)

ISn refers to plating a layer of immersion Tin over the copper trace. This surface finish is very suitable for SMT applications, BGA, and fine-pitch components.

Pros:

1. Cost-effective

2. Lead-free and RoHS compliant

2. Flat surface

3. High reliability

Cons:

The exposed tin will corrode easily.

2. Short shelf-life (about six months)

3. High sensitivity in the handling process

.........................................................................................................................................................................................................................................................

| Immersion Silver (IAg)

IAg is the surface finish of plating the immersion silver onto a board. Silver is the most conductive metal currently available. IAg is suitable for risk-free PCB assembly process and fine-pitch technology, especially high-speed PCB applications.

Pros:

1. Cost-effective

2. Excellent solderability

3. Flat surface

4. High stability and high conductivity

Cons:

1. Tarnish

2. Silver whickering

3. Creep corrosion

.........................................................................................................................................................................................................................................................

All the surface finishes have advantages and disadvantages. You need to choose the right type according to your PCB design, functions, storage time, process method, and application areas. And it is best to consult your PCB manufacturer about the cost differences and lead time of the surface finishes. Please contact us for more information before you placing orders if you are still confused about the choice.