What Is The Difference Between a Rigid PCB And a Flex PCB?

What Is The Difference Between a Rigid PCB And a Flex PCB?

When it comes to PCB (printed circuit board), a lot of people think of rigid PCB. But a PCB can refer to either a rigid PCB or a flexible PCB, and many customers feel confused about the difference between rigid PCB and flexible PCB. However, rigid PCBs have the same ultimate function as flexible PCBs, which is connecting various electrical and mechanical components together Now PCBGOGO will explain which one is best for your electronic project.

Some similarities and differences between rigid PCBs and flex circuits

When designing rigid PCBs, certain design rules must be followed, including minimum hole sizes, minimum space and trace width, minimum distances to board edges, and copper and overall design thicknesses. Additionally, many manufacturing process steps are shared between rigid and flexible PCBs. Such process steps include the drilling and plating of holes and vias, photo imaging and development, the etching of copper traces, pads, outlines, and planes, and the heating (baking) of the circuit boards for the purpose of removing moisture from the PCBs. At this point in the manufacturing process, rigid PCBs head to the solder mask station while flex circuits go to the coverlay station.

IPC Standards for Rigid and Flexible PCBs

There are the list of IPC standards applying to rigid PCBs and flex circuits as follows.

IPC-2221A, Generic Standard on Printed Board Design

IPC-2223, Sectional Design Standard for Flexible Printed Boards

IPC-4101, Specification for Base Materials for Rigid and Multilayer Printed Boards

IPC-4202, Flexible Base Dielectrics for Use in Flexible Printed Circuitry

IPC-4203, Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films

IPC-4204, Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry

IPC-6013, Qualification and Performance Specification for Flexible Printed Wiring

Rigid and flexible PCB design considerations difference

Most rigid PCB design elements have been applied in the design of a flexible PCB. However, there are some other new elements that require attention.

1. Current carrying capacity of the wire

Since the flexible PCB heat capacity difference ( compared to rigid PCB purposes ) , it is necessary to provide sufficient wire width . Some wires carrying large currents or adjacent to each other when placed face to face , considering the heat concentration problems , must be given an extra wire width or spacing.

2. Shape

No matter where in the case of possible rectangle should be preferred , because it can save a good base . Near the edge of freedom should allow sufficient margins , depending on the substrate may be the remaining space.

In shape , rounded angles should look ; pointed angles may cause the tear panel .

Smaller conductor width and spacing should be minimized as much as possible . If the geometric space permits, should be tightly packed into a thin wire width wire. Plated through holes in the wire or component mounting holes at the termination of the search to be smoothly over pads . As a general standard , any necessary transition as smooth as the angle from straight or change to a different line widths . Sharp natural causes stress concentration caused by lead failure.

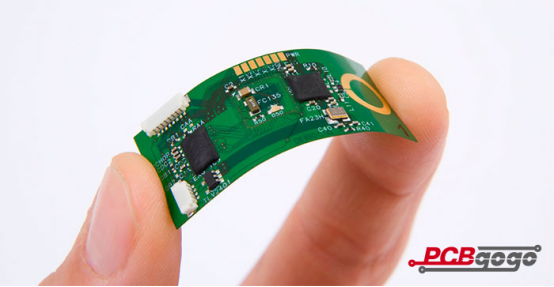

3. Flexibility

As a general standard , the bending radius should be designed to be as large as possible . The use of thinner laminates ( eg: 125μm 50μm copper foil instead of the wire and a wider, it can better withstand more improved possibilities for large cyclic bending of bending cycles, single-sided flexible PCB is usually displayed. better performance.

4. Pads

Around the pad , there is a change from a flexible material to a rigid material. This area of the conductor more easily damaged . Therefore , the pad should be avoided in the area prone to bending . The general shape of the pad should be such as teardrop-shaped , film must be able to cover the bonding pad seam.

5 . Rigid reinforcing plate

In the small electronic devices ( such as a small calculator ) in mass production , in combination with rigid laminates reinforced flexible PCB seizure board has become very popular, but it is also more cost optimization . Flexible PCB is equipped with a suitable slot in a rigid plate ( eg grade G-10) on to facilitate future separation. After assembling and soldering components connected by cutting the rigid plate into different parts, so as to be folded into the shape you want.

When to use rigid PCB and when to use flexible PCB

In general, rigid PCBs is more cost-effective than flex circuits. If you take the total cost of ownership into consideration, you should use flexible PCBs as it may be cheaper compared to rigid PCBs. To get a true and accurate understanding of the total cost if ownership, first of all, you need to know that flex circuits may remove the need for components, such as wire harnesses, connectors, as well as other circuit boards. What’s more, it will reduce the assembly and labor cost, material cost and scarp cost with removing these components from a design.

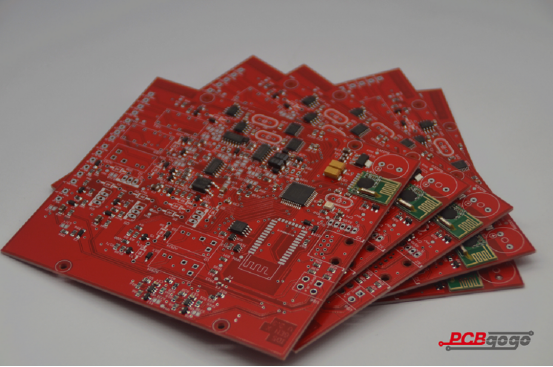

There are a lot of electronic devices using rigid PCBs instead of flexible PCBs, such as laptop and desktop computers, audio keyboards, solid-state drives (SSDs), flat-screen TVs and monitors, children’s toys, and various electronic gadgets. But it can find the flexible circuits in ultra-compact and high-performance devices, including GPS units, smart phones, tablets, cameras, and wearables.

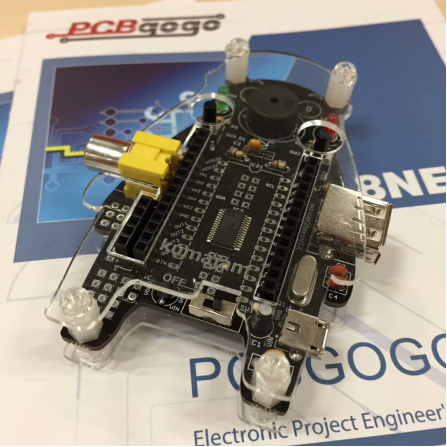

Your rigid PCB and flexible PCB in PCBGOGO

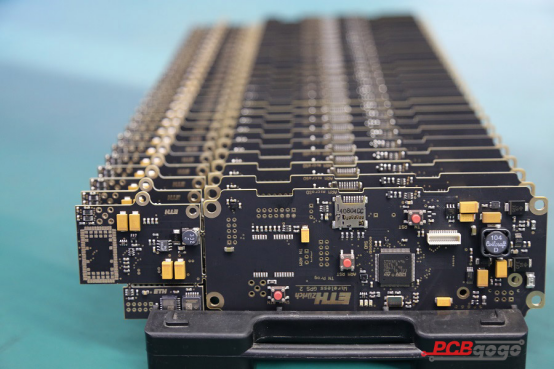

With over 10 years as an industry leader, PCBGOGO is one of the most experienced PCB and PCB assembly manufacturer in China. highly specialized not only in quick-turn PCB prototype and PCB assembly, but also medium and small volume PCB fabrication. We can provide rigid PCB and flexible PCB for you, and we will try our best to meet your demands on PCB fabrication.

If you have any questions, please feel free to contact us with service@pcbgogo.com, we will be happy to help you.