What is the PCB layer stack-up?

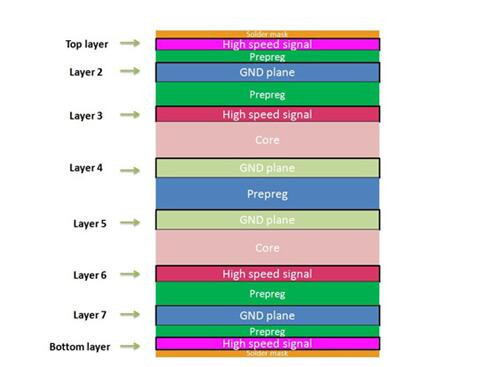

PCB layer stack-up, also called layer build-up, is the arrangement of insulating layers and conductive layers (copper layers) that make up the PCB before PCB layout design. Several insulating layers and copper layers are stacked together through the “prepreg” to generate a multiple-layered PCB. Here is an example layer stack-up of an 8-layer PCB.

____________________________________________________________________________________________________________________________

Why need layer stack-up?

The demand for PCB layer stack-up is the result of the miniaturization, lightweight, and the multifunction of electronic products. The requirements for excellent performance and high reliability make multi-layered PCB popularity.

As the PCB densities and complexities are increased to adapt to the development of electronic products, the efficiency of la yer arrangement must be improved to avoid the problems such as cross talk, stray capacitance, noises, then achieve the purpose of improving the signal integrity.

____________________________________________________________________________________________________________________________

The benefits of a well-designed layer stack-up

A poor-stacked PCB may increase the electromagnetic interference (EMI) and greatly lower the performance and reliability of the product. But a well-designed PCB layer stack-up help reduce the problems of signal cross talk and impedance mismatch on high-speed PCBs. And a useful stack-up will minimize the radiation and prevent the circuits from being interfered with by the outside noises. Besides, a well-stacked PCB provides better electromagnetic compatibility for your PCB design.

____________________________________________________________________________________________________________________________

Some considerations and rules about PCB layer stack-up

● The PCB structure should be designed based on the board size, circuit size, and EMC requirements.

● The layer distribution should be symmetrical or balanced.

● The thickness and the type of board materials are determined based on the characteristics of the materials,

the thickness of the inner layer, the manufacturing process, etc.

● Arrange the signal layer next to the internal power layer for tight coupling and avoid two signal layers is

adjacent to each other.

● The space between layers should be as small as possible to meet the requirement of miniaturization.

● The copper weight, the position of the vias, and the vias types should be determined according to the

specifications of your design.

____________________________________________________________________________________________________________________________

PCB layer stack-up of PCBGOGO

An optimal multilayer stack-up is one of the most critical factors determining the performance and reliability of a product. PCB designers should pay more attention to layer stack-up design.

PCBGOGO provides multilayer PCBs with layers from 4 to 14, and the board thickness ranges from 0.4mm to 3.0mm, the copper weight from 1oz to 4oz. The minimum space between layers can be 0.1mm (4 mils). We have default layer stack-ups for you choose, and we also provide customized layer stack-up for your PCB. Check our Standard stackup for multilayer pcbs.You can use the quote tool on our website for a rough manufacturing price and lead-time if you are planning to turn your PCB design into reality. Or you can contact us directly to get all the details you need.