What Is LED PCB?

Table of Content

1. What is LED PCB?

2. The advantages of LED PCB

3. The LED lighting industry

4. The application of LED PCB

5. SMD LEDs in your PCB

With the development of electronic technology, PCB lays a good foundation for a various of electronic products, such as the development of PCB for LED lighting. A prime example is the development of the PCB for LED lighting. The LED is soldered to the circuit board and features a chip that creates the light when electrically connected. A thermal heat sink and a ceramic base are used to bond the chip.

It is difficult for an LED PCB board to cool with traditional methods because it tends to create a high volume of heat. So metal core PCBs are often chosen for LED application as their enhanced ability to dissipate heat. Especially aluminum is often used to fabricate circuit boards for LED lights. The aluminum PCB typically includes a thin layer of thermally conductive dielectric material that can transfer and dissipate the heat with much greater efficiency than a traditional rigid PCB.

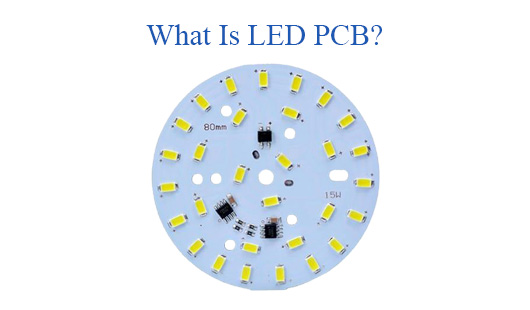

What is LED PCB?

A PCB with LED components soldered is usually called an“LED PCB”. It provides a physical and electrical platform for LEDs to operate safely and efficiently in lighting products.

LED is an acronym for light emitting diode, which is a semiconductor diode. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Needless to say, LED PCB is the core of LED lighting, and an LED circuit board is easy to create a high volume of heat, making it hard to cool with traditional methods. So metal core PCB is widely used in LED applications because of their enhanced ability to dissipate heat, especially aluminum is often used to fabricate PCB for LED lights. In general, the aluminum PCB contains a thin layer pf thermally conductive dielectric material that can transfer and dissipate the heat with much greater efficiency than a traditional rigid PCB.

Now SMD packaging type is the most widely used packaging form in LED applications. In general, it’s limited for the light emitted from a single LED component. So multiple LED components would be used for a single light fixture to achieve sufficient light. Like other semiconductor devices, PCB is the best method to electrically connect the LED components.

The advantages of LED PCB

As the electronic products are smaller and thinner, LED PCBs become more popular, and there are various advantages to using LED PCBs as follows:

· Lightweight, low profile

· dimensional stability

· thermal expansion

· Better heat dissipation

· Lower cost backlit membrane switch

· Dust and moisture resistant

· Make it easy to integrate into complex interface assemblies

· Efficient low power consumption

· Available in a wide variety of sizes, colors, and intensities

· May be used in silver flex membrane switches and copper flex membrane switches.

Two main reasons make the LED PCB popular, in addition to increasing the light output of the fixture with integrating multiple LED components.

1. It’s easy to tune the color function by integrating the LED components with different color temperatures or different colors into the same PCB.

2. It can achieve the various light fixtures to meet different lighting requirements with the boards that have different shapes, sizes and materials.

Types of LED PCB By Base Material

Here are 4 main types of LED PCBs commonly used in lighting and electronics applications:

1. Aluminum LED PCB (MCPCB): It is the most common substrate for LED applications due to its superior heat dissipation and cost-effectiveness.

2. Copper Core LED PCB: It provides the highest thermal conductivity among mainstream PCB materials, and is used when aluminum cannot meet performance requirements.

3. FR-4 LED PCBs: With relatively low thermal performance, it is commonly used in standard PCBs and os appropriate for low-power LED applications where heat is not a critical factor.

4. Ceramic LED PCB: It offers high thermal conductivity and excellent electrical insulation, making it ideal for specialized or high-reliability LED applications.

The LED Lighting Industry

LED lighting or light emitting diode is an increasingly popular lighting solution, so it’s popular to improve longevity and reduce environmental impact. There are some benefits of LED lighting for traditional methods as follows:

Lower power consumption: great LED lights with high quality can be six to seven times more efficient than traditional incandescent lights. On average, switching your home from incandescent lighting to LED lights can cut your energy use by more than 80 percent.

Longer Lifespan: LED light bulbs can have a life of over 25,000 hours, or three years of 24/7 use, which is 25 times longer than any traditional light bulb. So it saves you the time, money and effort involved in purchasing and installing new bulbs.

More Efficient: Traditional incandescent light bulbs release 90 percent or more of their energy as heat. LED lights cut this by up to twenty percent. It means more of your energy is going into lighting your home, and less into unnecessarily heating it.

Very Compact: LED lights have various sizes and types in applications due to their small size. It means manufacturers can insert LEDs into anything from computers and smartphones to cars and traffic lights.

Mercury Free: LED lights contain no mercury, unlike more traditional options. So LEDs have a smaller environmental impact than traditional bulbs and can be more easily disposed of, without special disposal procedures.

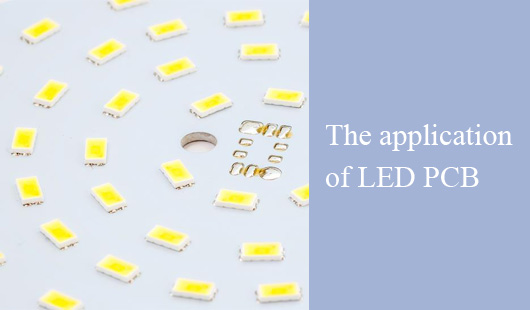

The application of LED PCB

PCB LED lights have excellent energy efficiency, low cost, and maximum design flexibility, so it can be incorporated into numerous lighting applications.

Telecommunications: LED indicators and displays are always used in telecommunications equipment due to the surrounding machinery, and they have a great heat transfer ability. Therefore, aluminum-based LED PCBs make a useful effect on their application.

Automotive: aluminum PCB LEDs are used for cars on indicators, brake lights, and in headlights, as well as other applications. There are some factors making the aluminum PCBs be ideal within the automotive industry, such as the durability and competitive prices.

Computer: LED displays and indicators are more and more popular in computer applications. And aluminum PCB LEDs are an ideal solution for them because of the heat sensitivity of computer machinery. Besides LED applications, aluminum PCBs are also used for computer parts like power devices and CPU boards due to their ability to dissipate and transfer heat.

Medical: Lighting tools used in surgeries and medical examinations commonly use high-powered LED lights, and these LED lights often use aluminum PCBs, which is primarily because of the durability and heat transfer capabilities of aluminum PCB LEDs — this makes sure medical equipment is functioning properly regardless of the number of patients cycling through a medical office. Except for lighting tools, medical scanning technology often uses aluminum PCBs as well.

SMD LEDs in Your PCB

There are many devices, including LEDs on a PCB Board using surface mounted components. If the wires are quite thin, through-hole components can bend slightly so that it looks cheap from the outside. If making it right to solder the SMD LED, it will be rigid on the board. What’s more, it can also place the SMD LED behind a screen, and cheaper LED that use a bulb will stick out through the packaging. So it can place the SMD LED behind a small screen in your packaging to be cleaner for your device. As you know, many PCBs that contain LEDs are fabricated with multilayer FR-4 substrates, so you need to have a pattern of closely-spaced filled or plated through vias under each component so that it can transmit heat, as well as get to your power and ground layers.

If your LEDs have a small footprint and are surface-mounted, it can use our vias. Probably there will be a weak solder joint or even tombstoning because it doesn’t fill or plate over the vias and then solder can wick into the vias during assembly, so the reason why it’s better to just use SMD LEDs on an LED lighting array is that the problem with wicking.

A single LED with decent power output will not lead to damaging to your board because of undue thermal. However, if you are going to have a system for lighting applications, it will need to suffer from a massive heat for the board that supports your LEDs, and make it hard to cool with traditional methods for the boards. Because the individual LEDs are too small, you can’t really attach a heatsink anywhere, and a heatsink will block the emitted light anyway. Because there is a great demand on thermal, the boards with a metal core are usually used in LED lighting applications due to their ability to dissipate a great deal of heat. In general, aluminum is used for LED lighting applications as the metal core in PCB. What’s more, aluminum is the most metal used as the core among all possible metal core PCBs. Copper and iron are used for metal core PCBs.

Conclusion

LED PCBs enable reliable lighting by integrating LEDs directly onto circuit boards, so as to manage heat and enhance performance. Their durability and energy efficiency make them ideal for compact and high-output designs across consumer, industrial, and commercial products.

As LED technology expands into fields like automotive, medical, and telecommunications, choosing the right PCB partner is key. PCBGOGO provides high-quality LED PCB manufacturing and assembly services, supporting both prototypes and mass production with engineering expertise and dependable delivery.