Solder Paste - Something You Need to Know

Solder Paste - Something You Need to Know

With the development of electronic technology, solder paste plays an important role in SMT, as well as it’s widely used in SMT PCB assembly, providing an easy to use medium for the solder. Solder paste can be used within large scale PCB assembly, or even prototype production. Because of the advantages, it has been a simple and easy process.

What is solder paste?

Solder paste, also called solder cream, a mixture of minute solder spheres held within a specialized form of solder flux, which is one of the important material used in the manufacture of printed circuit boards to connect surface mount components to pads on the board. As well as make it possible to solder through hole pin in paste components by printing solder paste in the holes. It’s a powder metal solder suspended in a thick fluid medium, which is called flux. solder paste is the form of solder that is used in association with infrared reflow machines during the PCB assembly process.

Solder paste classification

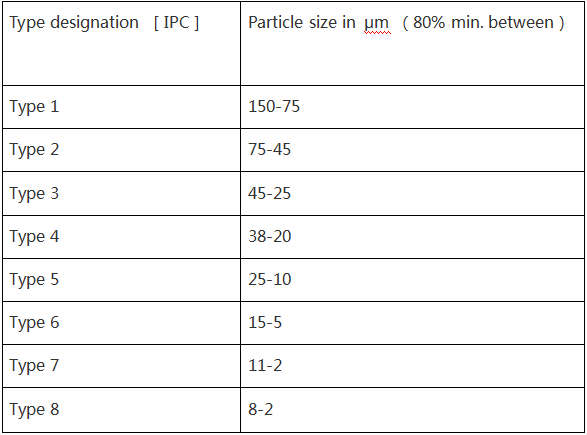

There are different types of solder paste and it can fit in with the PCB assembly process used. So the solder paste is classified based on the size of the small solder balls.

What’s more, solder can be classified into three types based on the flux types:

Rosin based solder pastes: rosin based pastes are made of rosin, a natural extract from pine trees. These fluxes can be cleaned if required after the soldering process using a solvent (potentially including chlorofluorocarbons ).

No clean solder paste: a no-clean flux is made with resins and various levels of solid residues. No-clean pastes save not only cleaning costs, but also capital expenditures and floor space. However, these pastes need a very clean assembly environment and may need an inert reflow environment.

Water soluble flux solder pastes: water soluble fluxes are made of organic materials and glycol bases. There is a wide variety of cleaning agents for these fluxes.

Properties of solder paste

There are some important properties of solder paste, which have a great effect on diverse circuit assemblies:

There are some properties of solder paste, which have a great effect on diverse circuit assemblies:

Viscosity: Viscosity is the property, it determines what a material resists against the tendency to flow. As the metal content increases, the viscosity increases to the point where the paste can no longer be printed on the board. As well as viscosity is related to temperature and it decreases with rising temperature.

Slump: slump means the spreading of a material after application. And it is mainly in depending upon temperature, viscosity of the plate, as well as height of paste deposited. However, the slump of a paste may create the risk of forming solder bridges or unequal deposit of paste between two adjacent lands, leading to a short circuit.

Rheology: rheology determines the flow and deformation of solder paste under certain conditions (such as temperature and pressure), which makes an effect on the depositing way of paste. In addition, rheology plays an important role in the print quality of solder paste.

Applications of solder paste in SMT

Because of the beneficial properties and features of solder paste, make it ideal for use in several applications. As they can be shown as follows:

Reflow soldering process: solder pastes are used for reflow soldering of surface mount assemblies. And it has a great effect on creating connection between the leads or termination of surface mount components.

Solder joints: solder paste is a homogenous mixture of solder alloy, flux and vehicles. The paste can be metallurgical bond with the given soldering conditions, so that create the reliable solder joints.

Lead components: solder pastes are used to create surface mount technologies (SMT) assemblies with leaded components, which is good for simplifying the design, lowering the fabrication cost, improving the component density, as well as increasing the reliability of the project.

Stencil printing: in general, solder paste is used for stencil printing, and the paste is deposited on the polyester mask or stainless steel to create the necessary pattern on the printed circuit board. It can be done with pin transferring or jet printing through the nozzles.

Some challenges with solder paste printing PCBs

There are a lot of challenges to consistently solder paste printing PCBs. And some unprofessional PCB assembly companies are easy to make mistake during the process, when complete the orders of mass production in haste with tight deadlines.

So PCB assemblers need to abide by some principles:

Create a perfect stencil: the accuracy of the stencil is depended on the accuracy of the process. Some poor printed stencil (such as the shoddy, the imprecise) will never create reliable results.

Program the screen printer properly: only to have accurate measurement and calibration can solder paste screen printing devices succeed in doing their work. and expert screen printing programming is a valuable skill in the PCB industry.

Apply the right amount of solder paste: redundant solder paste will form an imperfect outline, however a lack of solder paste will protect the surface mount devices from sticking.

Choose the right process: there are two main methods to achieve a good print, which are metal screen printing and mesh screen printing, the mesh screen printing is the cheapest method, but it can’t work on small surface mount devices that need precision attachment.

Turnkey PCB assembly in PCBGOGO

Solder paste is used in various surface mount devices. PCBGOGO is a specialist electronic manufacturing provider with extensive experience in PCB manufacturing and PCB assembly solutions for small to medium businesses. Min. quantity can be 5pcs. For over 10 years we have been proudly servicing customers all over the world with high quality boards and reliable, industry leading electronic manufacturing services right here from Shenzhen, China.

PCBGOGO has a workforce of approximately 400 people. We are proud of our reputation as a leading specialist in surface-mount, thru-hole and mixed technology PCB assembly and electronic manufacturing services as well as turn-key electronic PCB assembly.