Explaining Reflow Soldering for PCB Assembly by PCBGOGO

Explaining Reflow Soldering for PCB Assembly by PCBGOGO

When it comes to PCB assembly process, reflow soldering is the most widely used method of soldering, which is widely used for PCB assembly. It offers credible soldering for the all kinds of the sizes of component and pad required, as well as making it easy to control. The purpose of reflow soldering is to be acceptable soldering joints with pre-heating the components/PCB/solder paste first and then melting the solder, which instead of overheating without damage.

What is reflow soldering

Reflow soldering is a process, which using the solder paste to connect one or thousands of tiny electrical components to their contact pads, and then it will control the whole assembly by heating. The solder paste reflows in a molten stage to create the permanent solder joints. What’s more, heating can be done by passing the assembly with the reflow oven as well as under an infrared lamp or by soldering individual joints with a desoldering hot air pencil.

Reflow soldering technology, making it possible to reliably solder surface mount components, especially the components with very fine pitch leads. And it’s the best for use with components used in mass produced electronics products.

Preparation

Use the solder paste and components to the board is the first stage in reflow soldering for PCB assembly. Now PCBGOGO will explain the stage what is it.

Solder paste: substantively applying the solder paste to the board. And the solder paste is only used for the areas that require soldering. There is the solder resist layers on the board, but it’s essential to only add solder paste to the areas that require soldering, which is done by using the solder mask and solder paste machine. And it only allows the solder paste to be added to the PCB areas where it’s required. Then having been added the solder paste to the board after adding, it can go on to the next stage.

Pick and place: it can fix the components in place with the solder paste on the board. As usual using the automatic pick and place machine as it can’t work when using the manual placement to the numbers of components and necessary accuracy.

the pick and place machine places the components onto the board, and it can remain in place with the surface tension of solder paste. In fact, it is enough for normal handing, but there are some tips you need to know. It will be difficult to rework if the components glue to the board, then what’s worse, all the components in place will move to the reflow soldering machine.

Reflow soldering stage

The reflow process is made up of a lot of individual processes, which make sure there will not be any acceptable levels of thermal shock since the board is up to the correct temperature for reflow soldering.

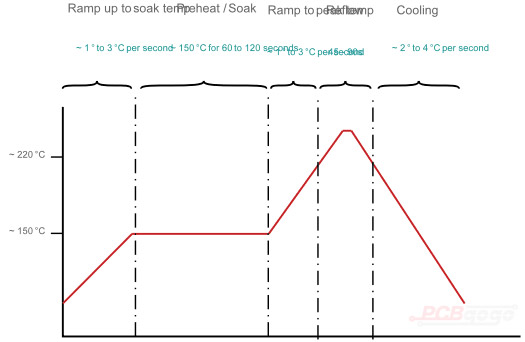

It can make sure the resultant solder joints have the highest quality if correctly analyse the temperature of the reflow tunnel or chamber. There are usually four stages as follows:

Preheat: the board need to be steadily up to the necessary temperature. However, it may be damaged by the thermal stress if the rate is too high.

In addition, some areas may not get to the necessary temperature due to the thermal mass if the temperature of PCB is too quick. However, it may not achieve the necessary temperature if it’s too slow.

in general, the temperature rise for infrared reflow soldering is between 2 and 3℃ per second, but it may be down to 1℃ per second on some occasions.

Thermal soak: after the board is rising in temperature, it will go into the thermal soak area. There are two reasons why the card us maintained at temperature, one is to make sure any areas that are not fully heated due to shadowing effects come up to the necessary temperature. The other is to active the flux and remove the solder paste solvents or volatiles.

Reflow: the area of reflow is the area where get to the highest temperatures in the soldering process. The solder is melting here and create the necessary solder joints. And the practical reflow process refers to the flux to reduce the surface tension at the metal joint so that achieve metallurgical bonding, allow the individual solder powder spheres to combine and melt.

Cooling: it needs to be done in a way without any stress to the components for the cooling boards after reflow. Appropriate cooling can restrain redundant intermetallic compound formation or thermal shock to the components. The range of typical temperatures in the cooling zone is 30-100℃ ( 86-212°F ), where is creating the relatively quick cooling rate for the temperature, and it can be a great grain structure in the solder with this method so that offer the most mechanically sound joint.

The key aspects that make a great effect on reflow soldering process as follows:

1. PCB/ component footprint design

2. Appropriate machine

3. Acceptable reflow profile

4. PCB, components and solder paste with high quality

5. Carefully printed PCB using well designed stencil

6. Repeatable placement of surface mount components

Reflow soldering for PCB assembly process in PCBGOGO

PCBGOGO is a specialist electronic manufacturing provider with extensive experience in PCB fabrication and assembly solutions for small to medium businesses. We can provide quick turn turnkey PCB assembly with high quality soldering that can meet the demands of electronics production areas.

If you have any questions, please feel free to contact us with service@pcbgogo.com, we will be happy to help you.