Electronic Project Engineer's Best Partner!

When it comes to metal core PCBs, Aluminum PCB is the most common type as the base material is made up of Aluminum core with standard FR-4. Aluminum PCB is the highly effective choice for the high-power applications which refer to heat dissipation and generally optimum performance, as well as maintaining and controlling the overall temperature of the project. Now Aluminum PCB has been widely used in LED lighting, power equipment and automotive systems.

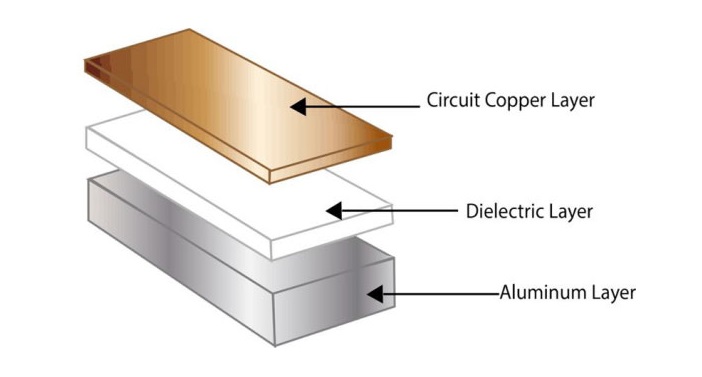

Circuit Layer: Printed circuit foil with thickness of 1 oz to 10 oz.

Dielectric Layer: The Dielectric layer is a thermally conductive layer and is around 50μm to 200μm thick. It had a low thermal resistance and it suitable for its application.

Base Layer: The base layer is most often Aluminum but can also be copper. The most commonly used thickness is 0.040" (1.0mm) although many alternative thicknesses are available.

| No. | Item | Process Capability Parameter |

|---|---|---|

| 1 | Base Material | Aluminum core |

| 2 | Number of Layers | 1 Layer, 2 Layers, 4 Layers, 6 Layers, 8 Layers |

| 3 | PCB Size | 1 Layer & 2 Layers:1200*300mm or 600*500mm Multi-layers: 600*500mm |

| 4 | Quality Grade | Standard IPC 2 |

| 5 | Thermal Conductivity (ω/m-k) | 1W, 2W, 3W, 8W, 12W |

| 6 | Board Thickness | 0.8-2.0mm |

| 7 | Min Tracing/Spacing | 4mil / 4mil |

| 8 | Plated Through-hole size | ≥0.2mm |

| 9 | Non-Plated Through-hole size | ≥0.8mm |

| 10 | Copper Thickness | 1oz, 2oz, 3oz, 4oz |

| 11 | Solder Mask | Green, Red, Yellow, White, Black, Blue, Purple, Matte Green, Matte Black, None |

| 12 | Surface Finish | HASL with lead, HASL lead free, Immersion Gold, OSP, Hard Gold, ENEPIG, Immersion Silver, None |

| 13 | Other Options | Countersinks, Castellated Holes, Custom Stackup and so on. |

| 14 | Certification | ISO9001, UL, RoHS, REACH |

Thanks to the premium performance, Aluminum PCBs have been widely used in the areas including LED lighting, power conversion, automotive, audio device, power supply, communication electronic equipment, motor drivers, etc. We welcome your inquiry about our Aluminum PCBs: service@pcbgogo.com