With the continued miniaturization of electronics and the circuitry, there is a great demand for conformal coating. It is worth mentioning that PCBGOGO has been fabricating the printed circuit boards with conformal coating two years earlier, and is the first PCB manufacturer to put on production in China.

What is the conformal coating?

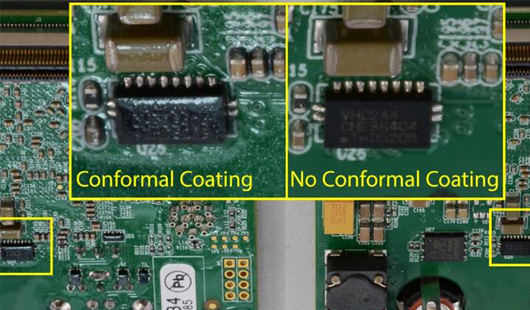

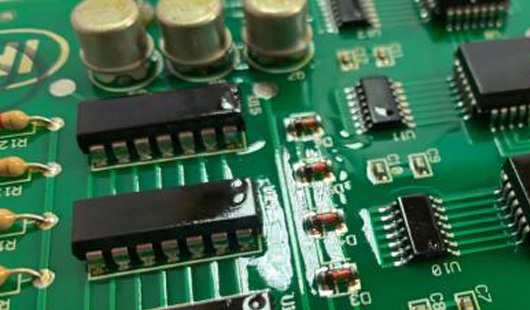

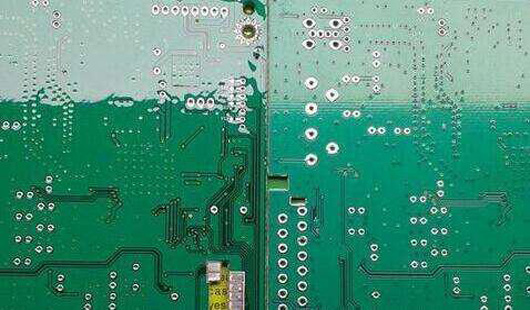

Conformal coating is a protective chemical coating of polymeric material applied in thin layers to printed circuit boards and electronic PCB assemblies, aiming at protecting electronic circuits and the component from harsh environments that may include high humidity, a range of airborne contaminants and varying temperatures so that highly improve the longevity and reliability of the component and the circuitry. In general, the film is applied at 25-250μm and ‘conforms’ to the shape of the board and its components, covering and protecting solder joints, the leads of electronic components, exposed traces, and other metallised areas from corrosion, ultimately extending the working life of the PCB.

Needless to say, it’s necessary for us to strengthen protection when today’s complex electronics are exposed to harsh conditions so that ensure its normal function. And conformal coatings can protect electronic components from the environmental factors, which may be moisture, dust, salt, chemicals, temperature changes and mechanical abrasion, and so on. What’s more, the successful conformal coating can prevent the board from corroding, and reduce the effects of mechanical stress and vibrations on the circuit and its performance in extreme temperature ranges. So there are some functions for the coatings as follows:

1. Insulating properties can allow a reduction in PCB conductor spacing

2. Avoid the demand for complex, sophisticated enclosures

3. Minimal effect on component weight

4. Completely protect the assembly against chemical and corrosive attack

5. Eliminate performance degradation due to environmental hazards

6. Minimize environmental stress on the PCB soldering.

Types of conformal coating

There are typically four types of conformal coatings based on the basic resin of each coating: Acrylic, Urethane, Silicone, and Epoxy, each option having its own beneficial properties for the different environments the printed circuit board will be operating in. So the operational requirements of the electronics make a direct effect on choosing the proper conformal coating for your application.

Acrylic coatings

Acrylics combine competitive prices with good environmental protection, they keep clarity and can prevent them from darkening and hydrolysis during extended exterior exposure. However, there is a limited solvent resistance, making them appropriate for rework but not applications where chemical resistance is important.

· Acrylic coatings have good flexibility and all round protection

· Easy to remove and apply and dry quickly at room temperature by simple solvent evaporation

· Provide excellent humidity and salt mist protection

· Have great adhesion to a wide variety of substrates

· Have a wide operating temperature range

Polyurethane coating(urethane)

Comparing to acrylics, urethane coatings provide excellent chemical resistance and superior protection to solvents, abrasions, and humidity, also they have great dielectric properties, what’s more, they keep flexibility at extreme temperatures. So it’s quite multipurpose covering a board operating temperature range the same as acrylics.

· It can remove the polyurethane coatings with specialist products (CCRG)

· Great chemical resistance

· Good flexibility, especially at low temperatures

· Great dielectric properties

Epoxy

It’s also known as epoxy resins, which are chosen for their strength, chemicals, humidity, as well as resistance to abrasion.

· High chemical and abrasion resistance

· Good dielectric properties

· Good humidity resistance

· Useful to around 150 fC

· CTE closer to epoxy PCB substrate

Silicone Coatings

Silicone coatings, also known as silicone resins, which are the most resistant coatings to high-low temperatures or temperature fluctuations because of their more flexible nature. And they provide immense resistance to humidity and corrosion. These coatings provide a wide range of protection in both challenging and rapidly changing environments.

· Good all round protection

· Flexible

· Make it easy to process and proper for the applications requiring rework

· Wide operating temperature ranges

· Approved to IEC 61086

The requirements of conformal coating

1. All coating should operate no lower than 20 degrees Celsius. The circuit board will take in the humidity as a composite, so the conformal coating can’t play a role if it isn’t drying the board.

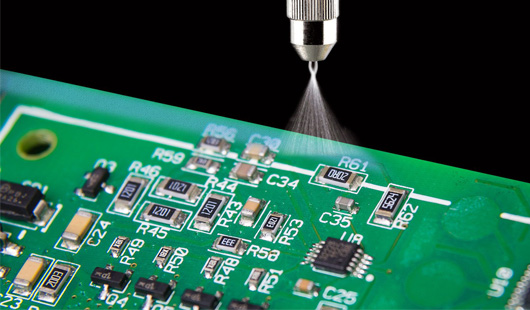

2. The thickness of HASL: it needs to control the thickness of the film between 0.05mm and 0.15mm. the thickness of the dry film is 25μm-40μm.

3. The drying film: it needs to dry with 20-30 minutes after coating so that making the film drying, and then the products can be worked after drying, but the film needs to avoid a collision in the process.

4. The curing of the film: it needs to make the film cure under the normal temperature of 8-16 hours.

5. The second coating: to make sure the products have a better thickness, it can do the second coating after curing the film. ( whether do the second coating or not based on your needs).

Some tips you need to know about the conformal coating

1. It needs to do with the breakaway tab in the PCB assembly process and the width should be greater than 5mm so that makes it easy to operate and work.

2. For custom PCB assembly, the maximum length and width of the circuit board is 410*410mm, the minimum is 10*10mm.

3. The maximum height of components is 80mm for the PCB assembly.

4. For PCB assembly, the Minimum spacing of components is 3mm between the coating areas and the non-coating.

Conformal coating for PCB

With over 10 years as an industry leader, PCBGOGO is one of the most experienced PCB and PCB assembly manufacturer in China. We are highly specialized not only in quick-turn PCB prototype and PCB assembly, but also medium and small volume PCB fabrication, needless to say, the satisfaction of customers is our goal, we will try our best to fabricate your circuit boards with the highest quality to meet your demands and committed to adhering to the strictest standards in PCB manufacturing and assembly.