Powertrain system of new energy vehicles has greatly demands on PCB

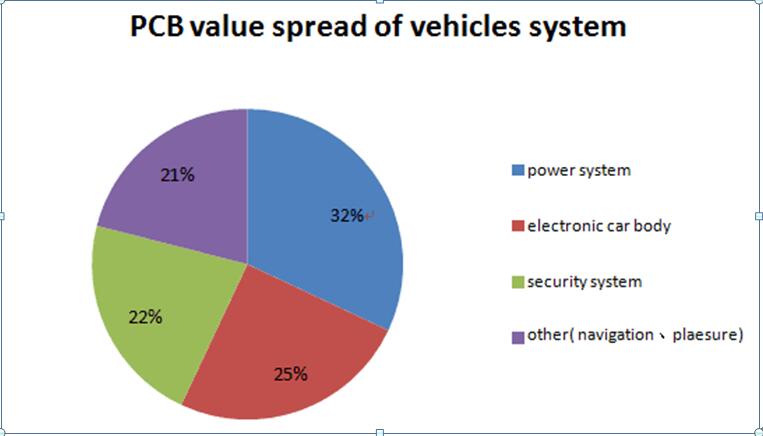

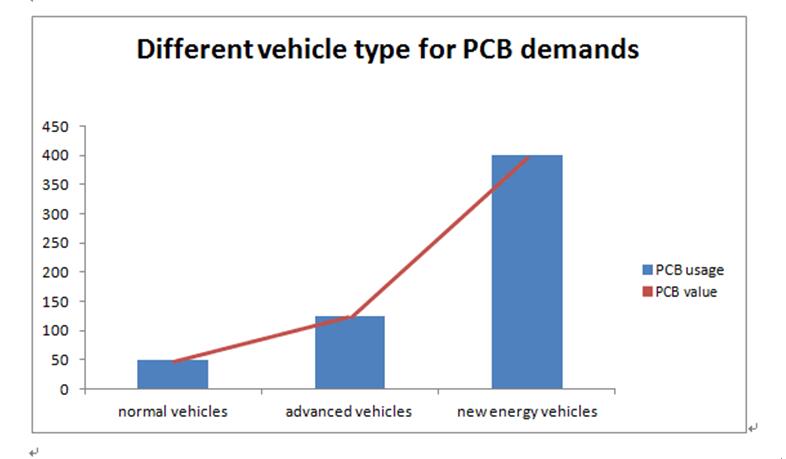

Nowadays, electronic rate of traditional automobile is normal, which has little demands on PCB and the value of PCB is low. PCB amount is about 2% in the cost of electronic devices, PCB amount of each automobile is about 1 sq.m with $60, high model is 2-3 sq.m with $120-130. Powertrain system has maximum demands on PCB with 32% share in the electronic component of traditional automobile, it mainly includes engine control unit, starter, generator, transmission control device, fuel injection, power steering system, etc; electronic system of car body is 25%, including automotive lighting、HVAC、power gate and seat、TPMS, etc; security control system is about 22%, including ADAS、ABS、SRS,etc; the rest is the vehicle electronic system of display、pleasure.

PCBGOGO, a fast PCB prototype manufacturer in the world, who has the individual idea: new energy vehicles have greatly demands on PCB because of unique powertrain system comparing with traditional automobile.

PCBGOGO says that new energy vehicles is mainly in pure electric vehicles and hybrids, the powertrain system of pure electric vehicles is made up of motor and power battery, driving system is easy. However, hybrids contains not only engine, but motor, which is mainly driving by fuel engine in the normal driving, but doing by motor as high level. The PCB substitute increment stems from MCU、VCU、BMS as powertrain system uses the electric drive in pure electric vehicles, fully replacing the driving system of traditional automobile. Superimposed increment of vehicles PCB will come into being as a set of new electronic driving is introduced for hybrids as retaining the driving system of traditional automobile.

It can be seen that PCB value increment of new energy vehicles is including superimposed increment of hybrids and the substitute of pure electric vehicles.

Superimposed increment of hybrids, just like the substitute increment of pure electric vehicles, which is the same for automobile board increment to stop distinguishing between hybrids and pure electric vehicles in the subsequent board increment test for automotive electronic value. Whether it is hybrid or pure electric, PCB increment is mainly in power control system: BMS、VCU and MCU. However, VCU is made up of control circuit and algorithms software, the control center of power system as monitoring vehicle status and making decision of vehicles power control. The control circuit of VCU needs PCB with 0.03 sq.m. MCU is made up of control circuit and algorithms software, the important role of mew energy vehicles electric control system as controlling motor’s working based on instructions of VCU to output alternating current. Control circuit, PCB is about 0.15 sq.m in MCU.

BMS: it’s the core component of battery unit, which takes and counts with voltage , current , temperature and SOC to control the battery during charge and discharge process and achieve protection and integrated management of battery. BMS hardware is made up of BCU and BMU, and BMU mounts in module to test single voltage , current , and balancing control; motherboard is flexible for relay control、SOC estimation and electrical harm prevention.

BMS is using multilayer boards with the better stability, and monomer value is higher than other circuit board as monitoring the voltage and current of the its battery to realize the balancing control, prevent the over-voltage and overcurrent from damaging the battery life and performance. BMS needs mass PCB because of complex framework, its main control circuit is about 0.24 sq.m and management unit is 2-3 sq.m.

The prices of product have great difference as different control unit has different demands on PCB process. For example, unit price of BCU circuit board can be as high as 20000yuan per sq.m, BMU board is 1500-2000 yuan per sq.m, PCB of VCU and MCU is normal board with low added value about 1000yuan per sq.m. Meanwhile, there is a difference between PCB amount of different vehicles because the number of monomer management units is different in each BMS with 3-5 sq.m on average, which is higher than traditional limousine with 2000yuan between 5-8 sq.m for PCB amount.

In recent years, passenger vehicle market of global new energy is booming, it’s calculated that 14.7 million passenger vehicle cars of global new energy were sold in 2013. It’s 35、55、77 million from 2014 to 2016, CAGR is up to 48.3%.

China, as the biggest new energy vehicles market in the world, the rate of expansion of market dimensions is higher than global average, Chinese new energy vehicles is up to 37.9 million and 51.7 million in 2015-2016, taking into consideration policy goal、integrating system and auto merchandising and so on, and it may be 70、100、120 and 150 million in 2017-2020, it will increase to 5% to market penetration.

It can be seen that new energy vehicles is making the market increment of 3 billion for Chinese automobile plate market. However, according to IEA’s counting, its overall sales will be up to 600 million in 2020 to estimate new energy vehicles will be taken 12 billion market increment to global automobile plate market.