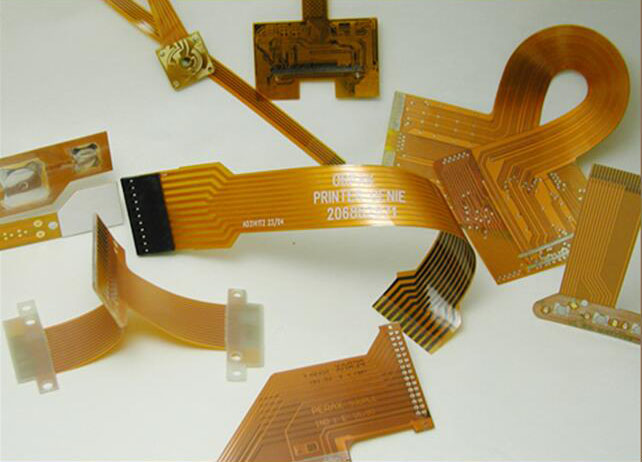

Flex circuits can easily be termed as circuits which are flexible or can flex. Flexible circuits are basically made from a thin insulating polymer film with a pattern of conductive traces mounted bonded onto the substrate. Flex circuits have been in use since the Second World War and they’re applications are still growing exponentially.

Types of Flex Circuits:

There are many types of flex circuits and here we will discuss the major ones

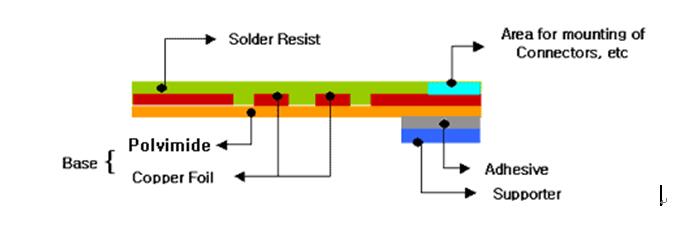

1: Single Sided Flex: Single sided flex circuits are the most basic and consist of a single layer of metal traces on one side of a dielectric layer. The dielectric can be polyimide or polymer. A polyimide overlay is added for insulation and protections from environmental degradation.

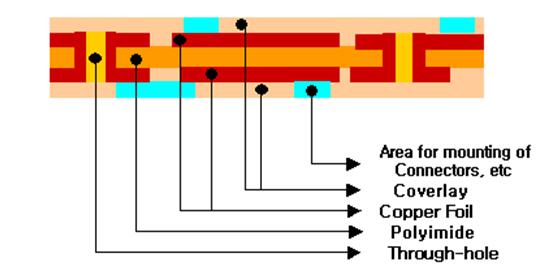

2: Double Sided Flex: A double sided flex circuit has multiple layers on both sides of a single dielectric layer. The two layers are plated by metalized through holes to make connections.

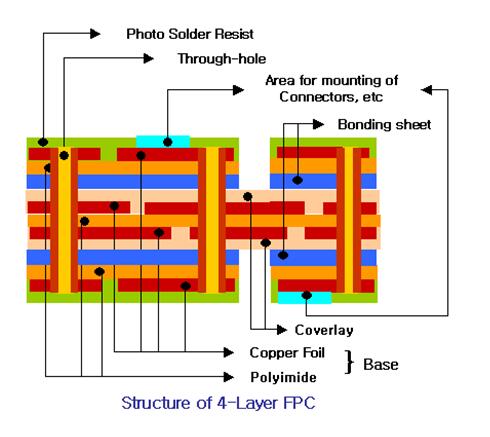

3: Multi-Layer Flex: Multi-Layer flex circuits has several copper layers separated by dielectric layers. The metal layers are again connected by through holes. There are more complex interconnections, layer design surface mounting.

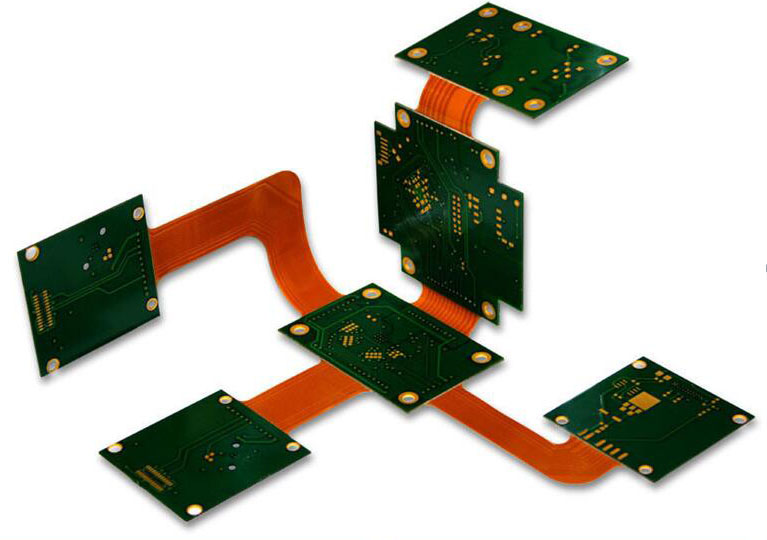

4: Rigid Flex Circuits: In rigid flex circuits the circuits consists of multiple circuit layers connected by an epoxy pre-preg bonding film, almost like a multi-layer flex circuit. Flex circuits are almost a combination of rigid circuit boards and flex circuits. Rigid flex circuits have higher component density.

Materials Used in Flex Circuits:

Now we will discuss the basic materials used in making flex circuits.

-

Conductors: Conductors allow the electrical current to flow freely. Copper is the most commonly used conductor while other materials used include aluminum, carbon, silver ink etc.

-

Adhesives: Adhesives are used for surface mount component binding. Adhesives are used according to the customer needs and thickness of conductor. Some adhesives that are used include epoxy, acrylic or PSAs (Pressure Sensitive Adhesives). Some circuits are built adhesive less.

-

Insulators: Insulators are used to separate electrical conductors without conducting current themselves. They are also used as support. Some common insulators include polyimide, polyester, solder mask, polyethylene naphthalene and polyethylene terephthalate.

Finishes: Finishes are made to protect the metal surface from oxidation. The final finish depends on the application of the circuit. Some common finishes include solder, tin, immersion in nickel or gold, silver, carbon etc

Benefits of Flex Circuits:

There are many benefits of flex circuits which make them more useful compared to traditional cables and rigid boards.

-

There is a huge decrease in assembly errors as the design is accurate and the production is fully automated.

-

They require less labor and reduce production errors. There is also a decrease in assembly time and costs.

-

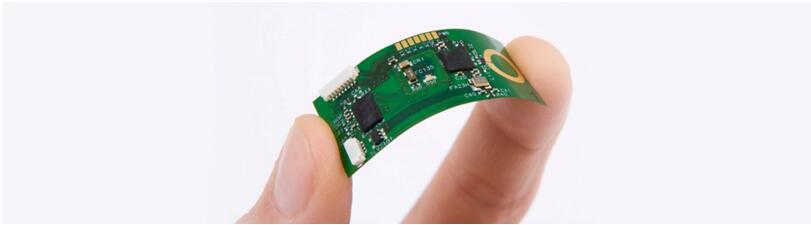

Flex circuits can be designed freely to meet all complex configurations. This is because of the flexibility it holds. The elastic nature also allows placement around edges and folds.

-

They reduce weight and take lesser space. Flex circuit boards contain the thinnest substrate materials. They can be as thin as 0.004 inches. This also reduces package size.

-

The flexible nature also helps to reduce and absorb the impacts of any vibration.

-

They are suitable for use in harsh environments. The thinner flex circuits also allow for increased heat dissipation. Similarly the streamlined flow allows for the flow of cooling air leading to improved airflow.

-

There is minimal use of mechanical connectors. There is also lesser use of interconnection points so the system is proven to be more reliable.

-

Rigid circuit boards require fewer parts and interconnections. Rigid circuits can also be built on complex configurations with reduced interconnections.

-

The rigid flex circuits also are proven to be denser with lighter components leaving additional space for more features.

-

Applications of Flex Circuits:

There are two basic types of applications of flex circuits:

-

Static Application: An application in which flex circuits are installed to fit into the specific application. It can be understood as a one-time bending. (also known as flex-to-fit)

-

Dynamic Flexing Application: An applications in which the flex circuit is bent multiple times as part of the application of the final product.

Flex circuits are being used in electronics such as calculators, cell phones, printers, LCD televisions. Cameras. They are used in the medical fields in heart monitors, pace makers, hearing aids. They are used in manufacturing of robotic arms, processing machines, bar code equipment etc. They are even used in satellites and GPS systems. In fact the applications are endless for flex circuits.

PCBGOGO IS OFFERING Flexible PCB boards at Low Cost

PCBgogo, one of the largest and most popular PCB manufacturers in Shenzhen, China. Built over 2400 sqm of land, this company specializes in manufacturing high-quality PCB’s (Printed Circuit Boards) in low price. These boards are custom designed according to your needs. Just looking at the “product categories” PCBgogo specializes in, we realize how much they have expanded over the years

These categories include data communication, optical networking, medical treatment, industrial control, aerospace/military etc. just to name a few.

Click Here to Quote Now