Why is the 01005 Component More Expensive in PCBA Manufacturing?

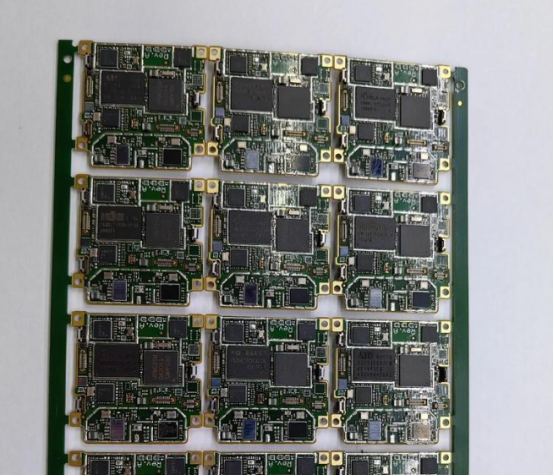

In the electronics manufacturing industry, particularly within PCBA (Printed Circuit Board Assembly) and SMT processing, the "01005 component" has become a hot topic. While this technology is essential for making electronic products smaller, thinner, and lighter, many clients are puzzled by its high price tag.This article explores the technical and economic reasons why the 01005 process commands a premium in the PCBA market.

What is the 01005?

The term "01005" refers to the imperial measurement of an electronic component's dimensions: 0.01 inches x 0.005 inches, which translates to approximately 0.4mm x 0.2mm.

These components are so microscopic they are nearly invisible to the naked eye. The 01005 process is the specialized Surface Mount Technology (SMT) required to accurately place and solder these tiny parts onto a PCB.

Key Characteristics of the 01005 Component

Ultra-Small Footprint: Its tiny size allows for extremely high-density integration in compact devices like smartphones, wearables, and medical implants.

Extreme Precision Requirements: Because the pads are so small, the tolerance for error is virtually zero. Even a microscopic deviation can lead to defects.

High Complexity: Handling 01005 components requires specialized feeders, high-resolution vision systems, and advanced vacuum nozzles.

Why is 01005 Assembly So Costly?

1. Expensive Equipment Investment

Standard SMT machines often lack the precision required for 01005 components. Manufacturers must invest in high-end, ultra-precision pick-and-place machines. Additionally, specialized Solder Paste Inspection (SPI) and Automated Optical Inspection (AOI) machines with higher resolution are required to verify the work, significantly increasing capital expenditure.

2. High Technical Threshold

The processing 01005 is not just about the machine; it’s about the expertise. Engineers must finely tune the reflow soldering temperature curves to prevent "tombstoning" (where a component stands up on one end). Operators require rigorous training to manage the delicate setup and maintenance of the feeders.

3. Stringent Material Requirements

At this scale, the quality of the PCB and solder paste becomes critical. The PCB must have a high degree of flatness and precise solder mask registration. Furthermore, the solder paste must use smaller powder sizes (such as Type 5 or Type 6) to ensure it can pass through the tiny apertures of the stencil.

4. Yield Rate Challenges

The difficulty of the 01005 process naturally leads to higher risks of assembly defects like bridging, shifting, or poor wetting. Achieving a high first-pass yield requires slower production speeds and more frequent quality checks, which adds to the overall manufacturing cost.

5. Supply and Demand

Only a limited number of tier-one manufacturers can reliably execute the 01005 process at scale. This specialized capability remains in high demand for high-end tech, keeping market prices elevated compared to standard SMT processing.

Conclusion

The high cost of the 01005 component is a result of the "precision tax"—the combined expense of advanced machinery, specialized materials, and elite technical skill. Despite the price, its ability to pack immense functionality into a tiny space makes it indispensable for the next generation of electronics.

At PCBGOGO, we specialize in high-precision PCBA services. We have the advanced SMT lines and expertise required to handle 01005, ensuring your high-density designs are manufactured with industry-leading accuracy and reliability.