Why is Selective Conformal Coating Critical for PCBs?

In the final stages of SMT processing, selective conformal coating has emerged as an indispensable specialized technique. This process involves using automated equipment to precisely apply a protective material—commonly known as "three-proof paint" (moisture-proof, salt-spray-proof, and mold-proof)—only to designated areas of the PCB. By giving critical components and solder joints a custom "protective suit," selective conformal coating addresses the core reliability issues of PCBs operating in harsh outdoor, industrial, and automotive environments.

Solving the Pain Points of PCB Failure

To understand the value of this process, we must first look at the environmental challenges PCBs face. Outdoor equipment is subject to rain, high humidity, and temperature extremes. Industrial devices struggle with dust, oil, and corrosive gases, while automotive electronics must endure thermal cycling and vibration. Without protection, these factors lead to solder joint oxidation and pin corrosion, causing short circuits or complete system failure.

Traditionally, "full-board coating" was used, where the entire PCB was dipped into the protective material. However, this method has two fatal flaws:

-

Blockage: It covers test points, connectors, and buttons that must remain exposed for assembly or debugging.

-

Waste: It consumes excessive material, driving up production costs.

Selective conformal coating solves these problems through "precision control."

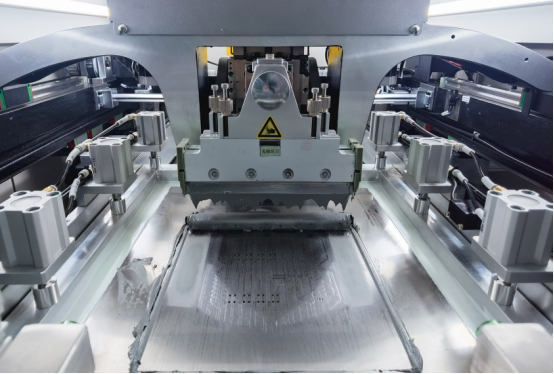

The Precision Process Behind the Protection

This is not a simple "spray paint" job. The process involves a highly technical workflow:

-

Programming & Positioning: Using the PCB’s Gerber files, the equipment is programmed to define "apply" zones (chip pins, resistors) and "keep-out" zones (connectors, sensors).

-

Masking Protection: For sensitive components like sensor faces, high-temperature tape or custom jigs are used to ensure zero contamination.

-

Precision Application: The machine nozzle moves with high accuracy to apply a uniform layer, typically between 20-50μm thick.

-

Curing: The board enters a curing oven where heat or UV light hardens the coating into a durable film.

Real-World Benefits for Reliability

-

Corrosion Resistance: The coating isolates the board from air and moisture, preventing oxidation. This is vital for PCBs used in chemical plants or marine environments.

-

Dust and Oil Protection: It prevents conductive dust and grime from accumulating on the circuit, which is essential for industrial control boards.

-

Thermal Shock Mitigation: The coating has a degree of flexibility that buffers the stress caused by thermal expansion and contraction, reducing the risk of solder joint cracking in automotive electronics.

At PCBGOGO, we recommend specific materials based on the application: acrylics for general use, polyurethanes for extreme temperatures, and silicones for chemical resistance. Our equipment maintains a positioning accuracy of $\pm 0.1\text{mm}$, ensuring that critical exposed areas remain untouched.

Conclusion

The core value of selective conformal coating lies in its ability to provide targeted protection without interfering with the mechanical assembly or electrical testing of the board. As the demand for high-reliability electronics grows, this SMT process remains the gold standard for extending the lifespan of products in demanding conditions.

Partner with PCBGOGO for your next project. We provide professional selective conformal coating services to ensure your PCBs are built to last, no matter where they are deployed.