Why is 50 Ohm Impedance commonly used in PCBs? 6 Key Reasons

When designing high-speed digital or RF boards, one number appears more than any other: 50 ohm impedance. Whether you are routing a microstrip or selecting a connector, 50 ohms is the undisputed industry standard. But have you ever wondered why we don't use 30 ohms or 80 ohms instead?

The dominance of 50 ohm impedance isn't an accidental choice. It is a calculated "golden compromise" shaped by history, physics, manufacturing constraints, and cost.

6 Key Reasons for Using 50 Ohm Impedance in PCBs

1. A Legacy of Global Standardization

During World War II, impedance values varied wildly depending on the specific application. As technology advanced, the industry needed a unified standard to ensure compatibility and economic efficiency.

The JAN (Joint Army Navy) organization in the United States eventually spearheaded this standardization. After evaluating factors like signal stability and reflection prevention, they settled on 50 ohms. This decision eventually spread globally, making 50 ohm impedance the default for almost all modern electronic systems.

2. The Ideal Balance for Power and Loss

From a physics perspective, 50 ohms represents a perfect middle ground. In the early days of coaxial cable design, engineers discovered a fundamental trade-off:

Maximum Power Handling: Occurs at approximately 30 ohms.

Minimum Signal Attenuation (Loss): Occurs at approximately 77 ohms.

By choosing 50 ohms, designers achieved a "sweet spot" that allows for high power transmission while keeping signal loss reasonably low. This is particularly vital for RF antennas and high-frequency communication.

3. Chip Driving Capabilities

In the early stages of semiconductor development, most chips simply didn't have the "strength" to drive transmission lines with very low impedance. Driving a 30-ohm line requires significantly more current than a 50-ohm one.

While higher impedance (like 100 ohms) requires less current, it makes the lines more susceptible to electromagnetic interference (EMI) and crosstalk. 50 ohms became the most practical value that early silicon could handle without sacrificing performance.

4. Simplified Impedance Matching

In high-frequency PCB design, preventing signal reflections is critical. This requires matching the source, the trace, and the load. Because the world has standardized on 50 ohms, most RF components—such as filters, amplifiers, and connectors—are built with an internal 50-ohm match. Using a consistent 50 ohm impedance across your PCB layout makes the integration of these components seamless and minimizes signal distortion.

[Image showing signal reflection at an impedance mismatch point vs. smooth transmission in a matched 50-ohm line]

5. Manufacturing Feasibility and Yield

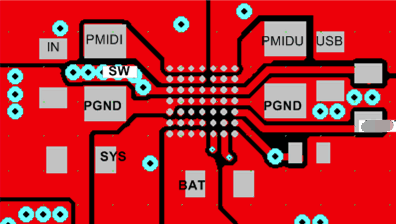

From a PCB fabrication standpoint, 50 ohms is "process-friendly." To achieve a specific impedance on standard materials like FR-4, you must balance trace width and dielectric thickness.

Low Impedance (<40Ω): Requires very wide traces or extremely thin dielectric layers, which eat up board space and are hard to implement on high-density boards.

High Impedance (>75Ω): Requires very thin traces. Thin traces are harder to etch accurately, leading to lower manufacturing yields and potential "open circuit" defects.

On a typical 1mm or 1.2mm thick board, a 50-ohm trace usually results in a width of 4 to 10 mils—a range that any standard PCB factory can produce with high precision and reliability.

6. Cost-Effectiveness and Compatibility

Because 50 ohms is the global norm, the ecosystem surrounding it is massive. Everything from test equipment (oscilloscopes and network analyzers) to cables and connectors is optimized for 50 ohms. Choosing this value reduces the need for custom components and specialized testing, which directly lowers the overall PCB manufacturing cost.

Conclusion

While certain specialized fields—like cable TV using 75 ohms for ultra-low loss—deviate from the norm, 50 ohm impedance remains the king of the PCB world. It provides the best balance of power, signal integrity, and manufacturability.

At PCBGOGO, we specialize in high-reliability multilayer boards with precise impedance control up to 32 layers. Whether you are working on 5G RF modules or high-speed computing, we ensure your 50 ohm impedance requirements are met with the highest manufacturing standards.