Should You SMT Mount or Depanelize First in PCBA Processing?

In the world of PCBA (Printed Circuit Board Assembly), the sequence of manufacturing steps is vital to the success of the final product. A common technical debate among engineers and project managers is: Should you SMT mount or depanelize first?

The order of these operations has a significant impact on production efficiency, overall cost, and the structural integrity of the components. To understand the best approach, let’s first look at the core processes involved.

Key Concepts: SMT mounting and Depanelization

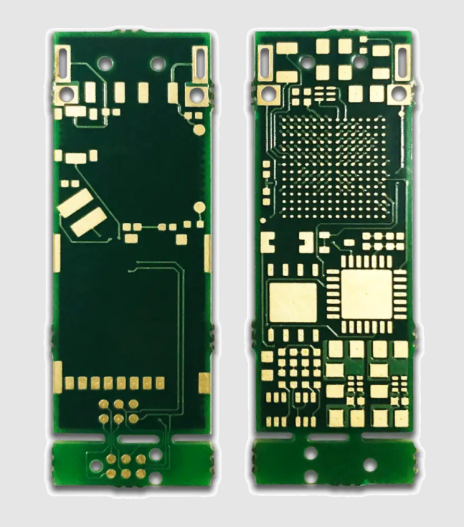

SMT (Surface Mount Technology): This is the process of mounting electronic components directly onto the surface of a PCB. It involves screen printing solder paste, high-speed component placement, and reflow soldering to create permanent electrical connections.

Depanelization: This is the process of separating individual PCBs from a larger "panel." Manufacturers use panels (multiple boards connected together) to streamline the assembly process. Depanelization occurs when these boards are cut into their final, individual shapes.

The Case for SMT Before Depanelization

In most high-volume manufacturing environments, SMT is performed on the full panel before the boards are separated.

High Production Efficiency: SMT machines are designed to process large panels. Mounting components on 10 or 20 boards at once is significantly faster than loading individual small boards into the machine.

Superior Alignment Accuracy: Working with a larger, rigid panel ensures that the PCB remains stable during high-speed component placement. This leads to better precision and fewer alignment errors.

Reduced Handling Risks: Keeping the panel intact reduces the number of times a board is touched or moved by robotic arms and human operators, lowering the risk of physical damage.

The Case for Depanelizing Before SMT

While less common for mass production, separating the boards before assembly (or working with single boards) has its own set of advantages.

Greater Flexibility: This approach is ideal for small-batch prototypes or "high-mix, low-volume" production where different boards require different handling.

Lower Equipment Barriers: Smaller setups do not require large-scale panel-handling equipment, making this a viable option for labs or smaller assembly shops.

Stress Prevention: Mechanical stress during the depanelization process (like snapping or routing) can sometimes crack sensitive ceramic capacitors or solder joints. By depanelizing first, you eliminate the risk of damaging already-mounted components.

Making the Choice: Which is Best for Your Project?

Mass Production

For large-scale manufacturing, the industry standard is to SMT first, then depanelize. The efficiency gains and the ability to use automated optical inspection (AOI) on a full panel make this the most cost-effective and reliable method.

Small Batches and Prototyping

For low-volume runs or highly complex designs with sensitive components near the board edge, depanelizing first might be safer. This ensures that the mechanical vibration of cutting the board doesn't compromise the quality of the delicate solder joints.

Special Requirements

If your PCB design is particularly dense or uses unconventional materials, the choice may be dictated by the specific "keep-out" zones near the edges of the board.

Conclusion

The decision to SMT mount or depanelize first depends entirely on your production volume, equipment capabilities, and the specific requirements of your hardware. Most enterprises prefer the efficiency of panel-level SMT, but single-board processing remains a vital tool for specialized applications.

No matter which method your project requires, PCBGOGO provides professional SMT assembly services tailored to your needs. With advanced equipment and strict quality control, we ensure your PCBs are assembled and separated with the highest precision and care.