PCB Routing Design Guide: Common Issues and Solutions

In PCB engineering, routing is the backbone of electrical performance, production feasibility, and long-term assembly reliability. As high-density, multi-layer, and high-speed impedance designs become the industry standard, PCB routing design issues have a more significant impact on manufacturing yields than ever before. Improper layout can lead to shorts, uneven copper distribution, impedance instability, and costly engineering reworks.

This guide summarizes frequent PCB routing design issues and provides Design for Manufacturing (DFM) recommendations to help engineers optimize their layouts and improve first-pass yield.

I. Fundamentals of PCB Routing Design

Before diving into specific problems, it is crucial to understand the key terminology associated with PCB routing design issues:

II. Common PCB Routing Design Issues & DFM Recommendations

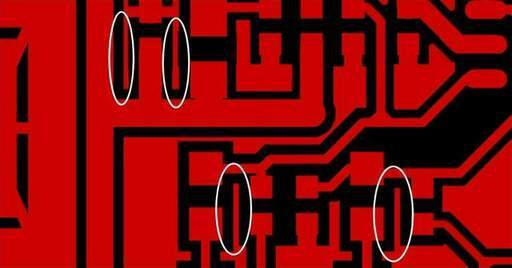

1. Dangling Traces (Dead Ends)

Issue: Traces that lead to nowhere or are not electrically terminated.

Quality Risk: These segments act as antennas for noise and are highly prone to causing accidental shorts during the etching process.

DFM Suggestion: Eliminate dangling traces during the design phase.

Note: CAM engineers often struggle to determine if a dangling trace is intentional or an error. Use DRC (Design Rule Check) to verify connectivity and line length.

2. Copper Strips at Board Edges

Issue: Designing bare copper strips along the PCB edge on every internal/external layer.

Quality Risk: Factory engineers may confuse these with "milling zones," leading to the accidental removal of functional copper.

DFM Suggestion: If bare copper is needed for grounding or shielding, define it only on the solder mask layer.

3. Extreme Variations in Copper Balance

Issue: Combining boards with very high copper density and very low copper density on the same production panel.

Quality Risk: This leads to uneven plating and etching. Areas with low copper might get over-etched, while dense areas might have residual copper bridges.

DFM Suggestion: Maintain consistent copper balance across the panel for uniform surface thickness.

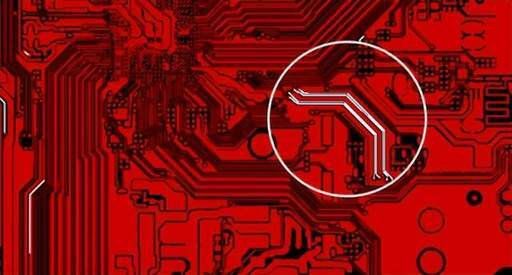

4. Overlapping Copper and Impedance Line Distinction

Issue: Stacking different copper pours or failing to distinguish trace widths for impedance-controlled signals.

Quality Risk: Increases CAM engineering time and risks impedance deviations in high-speed or differential pair signals.

DFM Suggestion: Clearly distinguish between copper pours and signal traces; use specific widths for impedance lines and mark them in the design documentation.

5. Router Bit (Milling) Clearance

Issue: Pouring copper too close to the milling path at the board edge.

Quality Risk: Manufacturers may assume this copper is "scrap" and trim it, or the milling bit may cause copper smearing/peeling, leading to edge shorts.

DFM Suggestion: Keep copper pours away from the router path. Ensure a clearance of $\ge 0.25mm$ from the board edge.

III. DFM Reference Values for Routing Design

To avoid common PCB routing design issues, follow these industry-standard reference values:

Conclusion

Mastering the nuances of PCB routing design issues is a vital part of the DFM process. Issues like dangling traces, poor copper balance, and insufficient milling clearance can result in electrical shorts, unstable impedance, and reduced assembly reliability. By adhering to strict design rules for trace width, spacing, and edge clearance, you ensure a high-quality, manufacturable product. For professional DFM reviews and high-precision manufacturing, PCBGOGO provides comprehensive services to optimize your routing and drilling, ensuring superior production yields and product reliability.