Optimizing PCB Board Outline and Panelization Design for Manufacturing Success

In PCB production, the design of board outlines and panels is critical to processing accuracy, assembly reliability, and mass production efficiency. Flawed PCB board outline and panelization design can lead to broken edges, V-cut scrap, dimensional deviations, and assembly difficulties. As high-density, multi-layer, and miniaturized products become mainstream, the Design for Manufacturing (DFM) requirements for these structural elements have become increasingly stringent.

This article summarizes common issues in PCB board outline and panelization design and provides DFM recommendations to help engineers optimize layouts, reduce production risks, and improve the first-pass yield.

I. Board Outline Design Issues and DFM Solutions

1. Avoid "Locked" Outlines

Issue: The design prevents access to internal slots or features by "locking" the outline path.

Quality Risk: This often leads to missing internal slots during fabrication.

DFM Suggestion: Do not lock internal slots; ensure the path is clear so the milling cutter can navigate through the board.

Technical Note: Explicitly define internal slot openings in CAD files to ensure the milling bit has an entry and exit path.

2. Insufficient Internal Slot Width

Issue: Internal slots are designed with a width of less than 0.8mm.

Quality Risk: The smallest standard milling cutter in the industry is 0.8mm. Anything smaller risks tool breakage or burrs.

DFM Suggestion: Design all internal slots to be $\ge 0.8mm$ to ensure smooth mechanical processing.

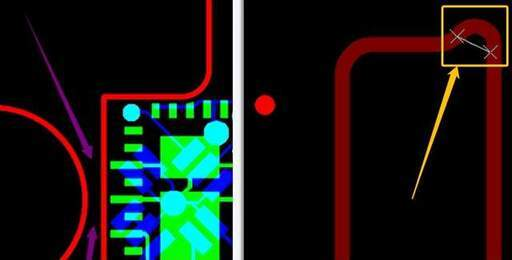

3. Overlapping Outline Lines

Issue: The design includes multiple or redundant lines for the board outline.

Quality Risk: Redundant lines confuse CAM software, leading to dimensional errors or repeated milling cycles.

DFM Suggestion: Ensure the board outline is a single, continuous, and unique closed loop.

II. Panelization Design Issues and DFM Solutions

A robust PCB board outline and panelization design must account for how the boards will be separated after assembly.

1. De-panelization Feasibility

Issue: Designing a panel without considering how it will be broken apart.

Quality Risk: V-cuts placed too close to components or complex shapes can lead to board scrap during separation.

DFM Suggestion: Increase the spacing at stress points and ensure the V-cut path is unobstructed.

2. Misaligned V-cut Lines

Issue: V-cut lines are not aligned on the same horizontal or vertical plane across the panel.

Quality Risk: Misalignment causes dimensional deviations and "copper leakage" if the blade hits a trace.

DFM Suggestion: All V-cut lines must be designed on a perfectly straight axis. Explicitly mark V-cut tolerances in your documentation.

3. Excessive Overhanging Edges

Issue: Large areas of the panel are left "floating" or overhanging without support.

Quality Risk: This leads to "board snapping" during V-cutting or "board jumping" during the milling process.

DFM Suggestion: Add auxiliary break-away tabs or use "stamp holes" (mouse bites) to reinforce the panel's structural integrity.

4. Ambiguous Panel Orientation

Issue: For square or circular boards, the orientation of the individual units within the panel is unclear.

Quality Risk: This often leads to assembly errors (components placed in the wrong direction).

DFM Suggestion: Use a clear "F" mark or utilize internal board features/fiducials to indicate the panelization direction.

III. DFM Reference Table for Outline & Panelization

To ensure your PCB board outline and panelization design is production-ready, refer to these standard values:

Conclusion

Mastering PCB board outline and panelization design is essential for balancing material utilization with manufacturing safety. By adhering to standards for slot widths, V-cut alignment, and structural reinforcement, engineers can significantly reduce the risk of mechanical damage and assembly errors. For high-precision projects, PCBGOGO offers specialized DFM reviews for board outlines and panels, providing expert guidance to ensure your boards are easy to manufacture, separate, and assemble safely.