Instrumentation PCBA Micro-Pitch Soldering Technology Manual Process: Optimization and Inspection Standards

With instrumentation technology advancing toward miniaturization and high precision, PCBAs increasingly adopt micro-pitch components (pin pitch ≤ 0.5mm), such as 01005 (0.4mm × 0.2mm), BGA, and QFP. Core challenges in micro-pitch soldering include solder bridging, open circuits, and excessive void rates, with industry average defect rates of 3–5%, seriously affecting instrumentation reliability.

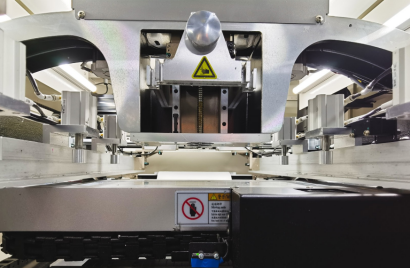

PCBGOGO, with a Class 10,000 cleanroom and Siemens high-speed SMT machines, can place 01005 components with ±50 μm accuracy, serving top instrumentation brands such as Philips and Siemens. This article presents process optimization, inspection standards, and full-process quality control based on IPC-A-610G and PCBGOGO’s SMT experience, helping reduce defect rates to below 0.3%.

Key Challenges and Industry Standards of Micro-Pitch Soldering

Core Difficulties

Small component size: 01005 pads are only 0.2mm × 0.1mm, requiring precise solder paste printing. A ±10% paste volume deviation may cause bridging or open circuits.

Narrow pin pitch: BGA ≤ 0.5mm, QFP ≤ 0.3mm; bridging and poor wetting are common.

Inspection difficulty: Some joints, like the bottom of BGAs, are invisible to the naked eye.

Thermal sensitivity: Excessive reflow temperature or long dwell time may damage precision components.

Industry Standards

IPC-A-610G Class 3: Void rate ≤5%, no bridging, solder wetting angle ≤30°

IPC-J-STD-001: Solder paste thickness deviation ≤±15%, placement deviation ≤±30 μm

IPC-7095: BGA solder joint shear strength ≥1.5N/point, no cracks or delamination

Common Defect Sources

Mismatched solder paste or insufficient flux

Low printing process accuracy

Placement machine deviation or nozzle wear

Improper reflow soldering curves

Limited inspection methods (missing X-RAY or AOI detection)

Micro-Pitch Soldering Full Process Optimization

1. Material and Equipment Selection

Solder Paste

01005: Lead-free, particle size 2–5 μm (Sn-3.0Ag-0.5Cu, MP 217°C), flux activity ≥0.8

BGA: Low-void solder paste, flux 12–15%

Imported brands: Alpha, Senju

Stencil Design

01005: 90% pad size (0.18mm × 0.09mm), thickness 0.12mm

BGA: Laser cut + electropolished, circular opening 0.25mm, pitch 0.5mm

PCBGOGO provides free stencil design review

Equipment

Printing: GKG-G5 (accuracy ±5 μm)

Placement: ASM Siemens (accuracy ±50 μm, repeatability ±30 μm)

Reflow: Jintuo (temperature control ±1°C, custom curves)

Inspection: EAGLE 3D AOI, Rilian X-RAY (accuracy 0.01mm)

2. Process Parameter Optimization

Solder Paste Printing

Pressure: 0.2–0.3 MPa, speed 20–30 mm/s, release 1–2 mm/s

Paste thickness: 0.12–0.15mm (±15% deviation)

SPI inspection: 100% coverage for paste volume, offset, bridging

Component Placement

01005: Nozzle 0.3mm, pressure 0.05–0.1 MPa, speed 30,000 points/hour

BGA: Visual + laser height detection, placement deviation ≤±30 μm, tilt ≤0.1 mm

Reflow Soldering

Preheat: 150–180°C, 60–90s

Soak: 180–200°C, 40–60s

Reflow: Peak 245±5°C, 10–15s

Cooling: ≤3°C/s, nitrogen reflow (O? ≤1000ppm)

Post-Processing

Manual soldering: Sn-3.0Ag-0.5Cu, 350±10°C

Cleaning: Environmentally friendly solutions to remove residual flux

3. Inspection and Quality Control

Online Inspection

AOI: Detect bridging, missing components, wetting issues, accuracy ≥99.5%

X-RAY: Check BGA/QFP voids, wetting, rework if void rate >5%

Offline Sampling

5% of each batch for visual inspection and shear strength testing (≥1.5N/point)

Traceability

PCBGOGO AI-MOMS system records full-process parameters and inspection data, ensuring traceable quality

Conclusion: Precise Control + Precise Inspection

Micro-pitch soldering for instrumentation PCBA relies on high-precision materials, optimized process parameters, and advanced inspection methods, strictly following IPC standards.

PCBGOGO, certified IATF16949 + ISO13485, offers full-service high-precision soldering, from 01005 placement to BGA/X-RAY inspection, supporting design, prototyping, and mass production with efficiency and reliability.

Recommendations

Follow PCBGOGO DFM guidelines during PCB design

Use small-batch prototyping to validate soldering

Leverage PCBGOGO’s bulk production capacity and ultra-precision placement technology for future micro-pitch advancements