How to Set the Perfect Lead-Free Reflow Temperature Profile?

In SMT (Surface Mount Technology) assembly, the transition from leaded to lead-free soldering hasn't just been a change in materials—it has redefined the precision required in the reflow oven. Lead-free soldering is notorious for its narrow "process window," where a few degrees can be the difference between a perfect joint and a damaged component. Setting the right lead-free reflow temperature profile is a delicate balancing act. Here is a professional guide on how to configure and optimize your lead-free reflow process.

1. Key Characteristics of Lead-Free Soldering

Before touching the oven controls, you must understand the thermal physics of lead-free alloys (typically SAC305):

Higher Melting Points: Traditional SnPb (Tin/Lead) solder melts at 183℃. Lead-free alternatives usually require at least 217℃.

Reduced Temperature Delta (△T): In lead-free processes, the temperature difference between the largest and smallest components on a board must be kept extremely tight—ideally less than 10℃. While large pins must reach at least 230℃ for wetting, small components must stay below their damage threshold (often 245℃ to 260℃).

2. Factors That Influence Your Temperature Settings

No two SMT lines are identical. Your settings must account for:

3. Pro Tips for Commissioning a Lead-Free Profile

If you are moving from a leaded to a lead-free process, keep these adjustments in mind:

Elevate the Preheat Temperature

To bridge the gap to the higher melting point, the preheat zone should be roughly 30℃ higher than a leaded profile. This reduces the "thermal shock" when the board enters the peak reflow zone and helps equalize temperatures across different component sizes.

Extend the "Soak" Time

Allowing the board to stay in the soak zone (150℃ to 200℃) slightly longer ensures that the flux is fully activated and that large BGAs reach the same temperature as smaller resistors before the final ramp-up.

Optimize the Reflow "Trapezoid"

Instead of a sharp "spike" at peak temperature, aim for a more trapezoidal curve in the reflow zone. By widening the time spent above the liquidus temperature (217℃), you ensure better wetting for high-mass components without needing to raise the absolute peak temperature to dangerous levels.

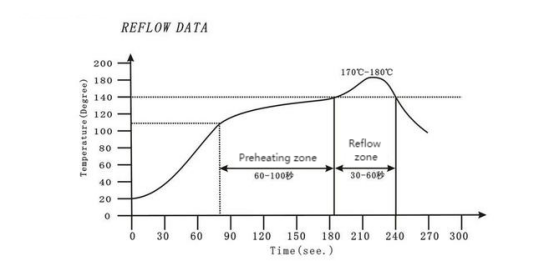

4. The Standard Lead-Free Reflow Curve

A successful lead-free profile is generally divided into four distinct stages:

Preheat Zone: Steady ramp-up (1-3℃) to evaporate solvents and begin flux activation.

Soak/Active Zone: Maintaining temperature to equalize the thermal mass of the PCB.

Reflow Zone (Peak): Rapidly heating to 10-20℃ above the melting point. Use at least two heating zones here to create a stable temperature plateau.

Cooling Zone: Controlled cooling to form a fine-grain solder structure without causing thermal stress cracks.

Conclusion

Achieving the perfect lead-free reflow temperature profile requires a combination of technical calculation and hands-on testing. By focusing on thermal equilibrium and following the specific requirements of your solder paste, you can ensure high-reliability joints even on the most complex assemblies.

For creators and engineers looking for flawless execution, partnering with a high-precision manufacturer is essential. PCBGOGO offers industry-leading SMT assembly services, utilizing advanced reflow technology and rigorous thermal profiling to ensure your lead-free projects meet the highest standards of quality and reliability.