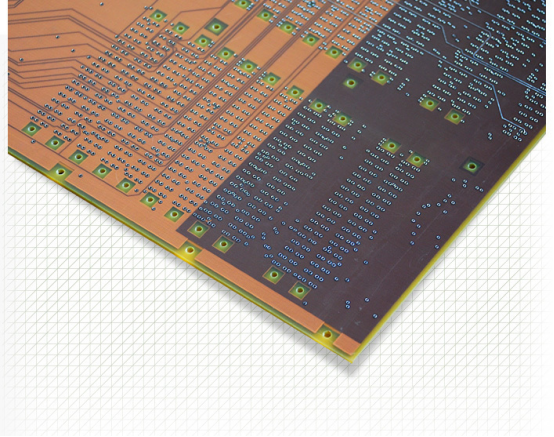

How to Eliminate 80% of Wave Soldering Defects via PCB Design?

Many engineers believe that wave soldering defects are purely process-related issues. However, at PCBGOGO, our experts have found that PCB design plays a decisive role in soldering quality. If the layout is flawed, even the most optimized process parameters cannot prevent failure. By focusing on a few critical design details, you can eliminate up to 80% of common wave soldering defects before the board even reaches the production line.

1. Optimize Pad Design to Prevent Bridging

The pad is the foundation of the connection between the PCB and the component. Improper pad sizing leads directly to solder balls, cold joints, and bridging.

Sizing: If pads are too large, solder disperses, failing to wrap around the pins; if too small, the solder volume is insufficient.

Standards: At PCBGOGO, we adhere strictly to the IPC-7351 standard and component datasheets to optimize pad length, width, and pitch.

Pro Tip: For rectangular pads, adding a small chamfer at the pin exit point helps guide solder flow and significantly reduces the risk of solder bridging.

2. Component Orientation and Layout

The direction in which components travel through the solder wave is vital for preventing wave soldering defects.

Parallel Alignment: Component pins should be oriented parallel to the direction of the wave. If pins are perpendicular, the solder cannot fully wet the pads, causing "shadowing" effects or cold joints.

Spacing: Inadequate spacing blocks the flow of liquid solder, leading to trapped solder balls.

Structural Support: Heavy components like transformers or large capacitors should be placed toward the center of the board rather than the edges. This prevents PCB warping caused by gravity and high temperatures during the wave process.

3. Via and Solder Mask Precision

Design details regarding vias and the solder mask often go unnoticed but are major contributors to soldering failures.

Via Placement: If a via is too close to a pad (less than 0.5mm), the molten solder can "wick" into the hole, leaving the pad starved of solder. If space is tight, consider using blind or buried vias.

Solder Mask Quality: If the mask encroaches on the pad, it ruins solderability. Conversely, pinholes in the mask can trap moisture or gas, causing solder splashes. PCBGOGO maintains rigorous control over mask thickness and curing temperatures to ensure a pristine surface.

4. PCB Thickness and Material Selection

The physical properties of the board itself influence the thermal profile of the soldering process.

Board Thickness: Boards that are too thin may warp under the heat of the solder wave. For high-density designs, a standard 1.6mm FR-4 substrate is often recommended to maintain flatness.

Thermal Conductivity: Poor thermal conductivity leads to insufficient preheating. Selecting high-quality materials ensures the board reaches the correct temperature uniformly, preventing thermal shock and incomplete wetting.

Conclusion

Quality control for wave soldering starts at the CAD workstation, not the factory floor. By refining your pad geometry, component layout, and via clearances, you address the root causes of production failures. Integrating these design best practices with PCBGOGO. With advanced fabrication capabilities allows you to eliminate the vast majority of wave soldering defects from the start.

Optimizing these design details is the most cost-effective way to improve your first-pass yield and ensure the long-term reliability of your electronic products.