HDI PCB Buried and Blind Vias: Design, Fabrication, and Yield Optimization

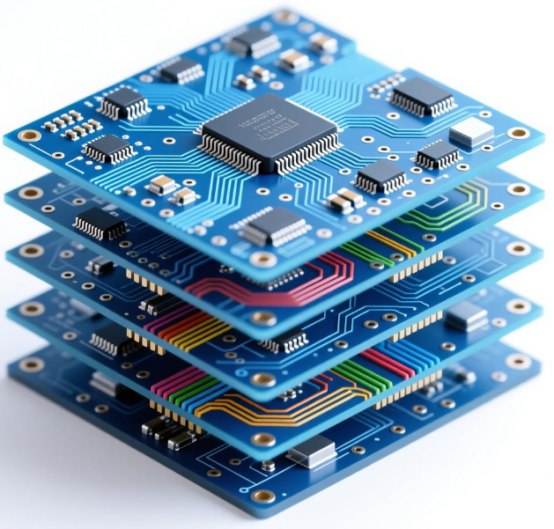

In the field of high-density interconnect (HDI) PCBs, the integration of buried and blind vias with advanced PCB stack-up design is a key pathway for achieving compact, high-performance electronics. Buried and blind via technology reduces surface via count and enhances routing density, while a well-planned stack-up ensures the reliability and electrical performance of the vias. At PCBGOGO, we combine stack-up design and via technology in HDI PCB R&D and manufacturing to deliver solutions that meet the demands of modern high-end electronic devices.

1. Understanding Buried and Blind Vias

Buried vias are located entirely within inner layers of the PCB and do not extend to the surface, connecting only internal signal layers. Blind vias, on the other hand, connect a surface layer to one or more internal layers but do not pass through the entire board. Compared with through-holes, buried and blind vias save surface space, shorten signal paths, and reduce electromagnetic interference (EMI).

In stack-up design, via placement and diameter must closely match the layer structure to ensure reliability and signal integrity.

2. Case Study: Second-Order Buried and Blind Vias in a 10-Layer HDI PCB

In one PCBGOGO project for a 10-layer smartphone motherboard, second-order buried and blind via technology was applied. The layer sequence was:

L1 (Top Layer) → L2 (Ground) → L3 (Signal) → L4 (Signal) → L5 (Power) → L6 (Power) → L7 (Signal) → L8 (Signal) → L9 (Ground) → L10 (Bottom Layer)

First-order blind vias connected L1-L3 and L10-L8

Second-order buried vias connected L3-L7

This design allowed high-density interconnections across signal layers while minimizing surface via usage, leaving more room for routing and component placement.

3. Key Design Principles for Buried and Blind Vias

Effective via design in HDI stack-up requires adherence to three principles:

Diameter and pad match – via diameter should not exceed 50% of layer thickness to prevent barrel cracking.

Avoid critical planes – buried and blind vias should steer clear of power and ground regions to prevent shorts or grounding issues.

Maintain spacing – keep sufficient clearance between adjacent vias (≥0.3 mm) to avoid copper foil shorts.

PCBGOGO leverages CAM software for precise via calculations, controlling barrel roughness to ≤5 μm, ensuring high reliability in multilayer structures.

4. Process Collaboration for High-Precision Vias

The success of buried and blind vias depends on close collaboration between stack-up design and fabrication processes. Via production involves drilling, copper plating, and electroplating, each requiring alignment with the stack-up plan:

Drilling: Select drill size and parameters based on layer thickness to avoid misalignment or burrs.

Copper plating: Ensure uniform plating thickness to maintain barrel conductivity and adhesion.

PCBGOGO uses high-precision drilling equipment and automated electroplating lines to achieve >99% yield in buried and blind via fabrication.

5. Cost Considerations in Buried and Blind Via Design

Second-order buried vias are more complex and expensive than first-order. Therefore, careful planning during the design stage is essential to balance performance, manufacturability, and cost. PCBGOGO offers integrated design–process–cost solutions, optimizing stack-up structures while maintaining product reliability and minimizing production expenses.

Conclusion

The combination of HDI PCB buried and blind vias with optimized stack-up design is essential for achieving high-density, compact, and reliable electronic products. By following design principles, collaborating closely with fabrication processes, and balancing performance and cost, manufacturers can fully leverage the advantages of buried and blind vias. PCBGOGO’s expertise in HDI PCB design and manufacturing ensures robust, high-performance interconnections for modern electronics applications.