A Comprehensive Guide to Outdoor PCB Shielding Enclosure Design

Outdoor Printed Circuit Boards (PCBs) operate in some of the most unforgiving environments on the planet. From intense UV radiation and torrential rain to salt spray and extreme thermal cycling, these components face a constant barrage of corrosive elements. Consequently, the standards for an Outdoor PCB Shielding Enclosure are significantly more rigorous than those for indoor applications.

While indoor shields primarily focus on electromagnetic interference (EMI), outdoor shields must function as a robust physical barrier against structural failure. Below, we break down the four critical requirements for effective Outdoor PCB Shielding Enclosure design and how they differ from standard indoor solutions.

Superior Material Selection for Weather Resistance

In the design of an Outdoor PCB Shielding Enclosure, material choice extends beyond simple electrical conductivity; "weatherability" is the priority. This refers to a material's ability to withstand UV light, moisture, and temperature fluctuations without degrading.

The Indoor Approach: Indoor shields often utilize cold-rolled steel with basic zinc plating, which is sufficient for climate-controlled environments.

The Outdoor Approach: For outdoor environments, 316 stainless steel is the gold standard due to its exceptional resistance to salt spray and acid-base corrosion. In high-temperature and high-humidity regions, a combination of copper alloy with nickel-gold plating is preferred for its UV stability and anti-corrosive properties. Experts suggest avoiding ordinary cold-rolled or galvanized steel, as these materials fail rapidly when exposed to the elements.

Enhanced Surface Treatment Thickness

A key differentiator for an Outdoor PCB Shielding Enclosure is the thickness of the protective coating. Because outdoor corrosive factors are persistent, thin coatings will eventually permeate and fail.

Increased Plating Layers: While an indoor shield might only require a 5–10μm zinc layer, an outdoor shield demands 15–20μm. Similarly, nickel plating should be increased from the standard 3–5μm to at least 8–10μm.

UV-Resistant Coatings: Ultraviolet rays can break down the molecular structure of standard surface treatments, leading to cracking or peeling. Integrating a dedicated UV-resistant topcoat is essential to ensure the longevity of the underlying protective layers.

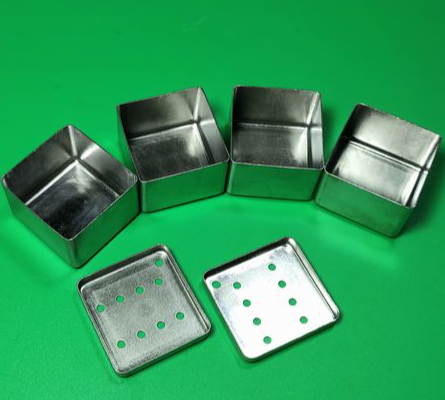

High-Integrity Sealing and Structural Design

Moisture and dust ingress are the primary catalysts for internal corrosion. Therefore, the structural integrity of the Outdoor PCB Shielding Enclosure must be far more sophisticated than a simple clip-on cover.

Seamless Construction: Joints should ideally be welded to create a continuous, impenetrable seal.

Sealing Gaskets: For shields that require maintenance access, a combination of mechanical buckles and high-grade gaskets is necessary. These gaskets should be made of weather-resistant silicone or fluororubber.

Edge Flanging: Incorporating flanged edges increases the contact surface area, further improving the seal. Additionally, applying a weather-resistant conformal coating over the shield can provide an extra layer of defense, provided the coating is rated for UV exposure to prevent cracking.

Integration of Corrosion Monitoring Systems

Maintenance for outdoor equipment is often logistically challenging and expensive. By the time corrosion is visible to the naked eye, the PCB may already be compromised.

Modern Outdoor PCB Shielding Enclosure design now incorporates proactive monitoring. By embedding corrosion sensors at critical points on the shield, engineers can track degradation levels in real-time. This data is transmitted to a central system, triggering an alert when the corrosion reaches a specific threshold. This "predictive maintenance" approach allows technicians to replace shields before the internal electronics suffer irreparable damage.

Conclusion: Indoor vs. Outdoor Shields

The fundamental difference lies in the stakes: indoor design focuses on cost-efficiency and EMI, whereas the engineering of an Outdoor PCB Shielding Enclosure focuses on survival and long-term reliability. By prioritizing high-grade materials like 316 stainless steel, increasing plating thickness, ensuring hermetic seals, and utilizing smart monitoring, you can protect your IoT devices and infrastructure from the harshest climates.

For projects requiring the highest standards of durability and precision, PCBGOGO provides the advanced manufacturing and material expertise necessary to bring these robust outdoor designs to life.