4 Essential Requirements for SMT Components: A Guide to Perfect PCB Assembly

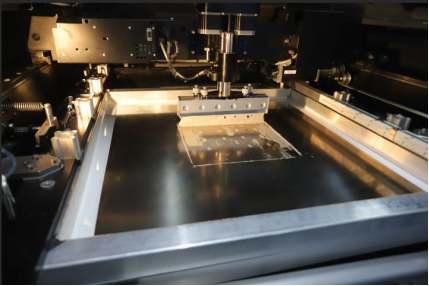

Surface Mount Technology (SMT) is the backbone of modern electronics manufacturing. By mounting components directly onto the surface of a Printed Circuit Board (PCB), SMT allows for high-density layouts and extremely efficient assembly. Compared to traditional Through-Hole Technology (THT), SMT offers clear advantages in terms of precision, reduced board size, and faster production cycles.

However, the high speed of automated assembly lines means that even small errors in material choice can lead to big problems. The success of an SMT run isn't just about having a great pick-and-place machine; it's about the quality of the components themselves. Here are the four critical requirements for SMT components to ensure a high-yield, defect-free production.

4 Key Requirements for SMT Components

1. Dimensional Tolerance and Lead Pitch

In SMT assembly, precision is everything. Automated machines rely on exact data to place components at high speeds, often within micrometers of their target.

Standardized Sizes: Components must strictly adhere to their specified package sizes (like 0402, 0603, or QFN). If a part is slightly too large or small, it can lead to placement errors or even damage the PCB pad.

Pitch Precision: The lead pitch—the distance between the centers of two adjacent pins—is vital. If the pitch is even slightly off, you run the risk of solder bridging (shorts) if the leads are too close, or cold joints (poor connectivity) if they are too far apart. Always ensure your component sourcing matches your PCB footprint design perfectly.

2. Surface Finish and Solderability

The leads or "terminations" of a component must be ready to bond with solder the moment they hit the reflow oven.

Finish Types: Common surface treatments include tinning (Sn), silver (Ag), or gold (Au) plating. These finishes are designed to facilitate "wetting," the process where molten solder flows and adheres to the metal.

Oxidation Control: If components are old or stored improperly, the leads can oxidize. Oxidized pins act as a barrier to solder, leading to voids or insufficient wetting. For long-term reliability, high-quality surface treatment is non-negotiable.

3. Component Packaging for Automation

How a component arrives at the factory is just as important as the component itself. SMT is an automated process, and the "packaging" determines how easily a machine can handle the parts.

ESD Protection: Components must be in anti-static packaging to prevent Electrostatic Discharge (ESD) from frying sensitive internal circuits before they are even soldered.

Moisture and Durability: Packaging should be moisture-proof and robust enough to handle the rigors of shipping without bending delicate pins.

Automation Formats: Depending on the production volume, parts should be provided in Tape and Reel (Reel) for high-speed chip mounters, Tubes for larger ICs, or Trays for delicate, high-pin-count devices.

4. Cleanliness and Contamination Control

A "dirty" component is a recipe for assembly failure. Contaminants on the component surface can interfere with the chemical reaction required for soldering.

Contaminants: Oil, dust, and fingerprints are the usual suspects. These impurities prevent the flux from cleaning the metal surface, which results in poor solder joints.

Post-Soldering Reliability: Even after soldering, cleanliness matters. Residual flux or debris can trap moisture over time, leading to dendritic growth or corrosion that kills the circuit in the field.

How to Maintain High Quality Control

Ensuring your components meet these requirements requires a disciplined approach to Quality Control (QC):

Strict Supplier Vetting: Work only with reputable suppliers who provide full traceability and strict adherence to dimensional specs.

Incoming Quality Control (IQC): Before parts hit the floor, perform spot checks for oxidation, pin pitch, and packaging integrity.

In-Process AOI: Utilize Automated Optical Inspection (AOI) during the assembly run to catch any placement or soldering issues in real-time.

Conclusion

SMT component requirements are demanding because the technology itself is built for perfection. By paying close attention to dimensions, surface finish, packaging, and cleanliness, you can significantly reduce rework, lower production costs, and build a more reliable product.

If you are looking for a partner who understands these technical nuances, PCBGOGO is here to help. As a leading SMT assembly service provider, we offer comprehensive turnkey solutions—from high-quality PCB fabrication to meticulous component sourcing and high-speed assembly. We handle every project with the precision your designs deserve, ensuring your products are market-ready and built to last.